Loose piece terminals are a specific type of connector designed for easy assembly and reliable electrical connections. These terminals are often used in applications where quick disassembly and reassembly are necessary, making them popular in both automotive and industrial settings.

One of the primary advantages of loose piece terminals is their versatility. They can accommodate various wire gauges and are compatible with different connector types, allowing for flexible design options. This adaptability makes them suitable for a wide range of applications, from simple wiring projects to complex machinery.

Installation of loose piece terminals typically involves crimping or soldering, which ensures a secure and stable connection. Proper installation is crucial, as it directly affects the electrical performance and longevity of the connection. Users must follow guidelines to ensure that the terminals are crimped or soldered correctly.

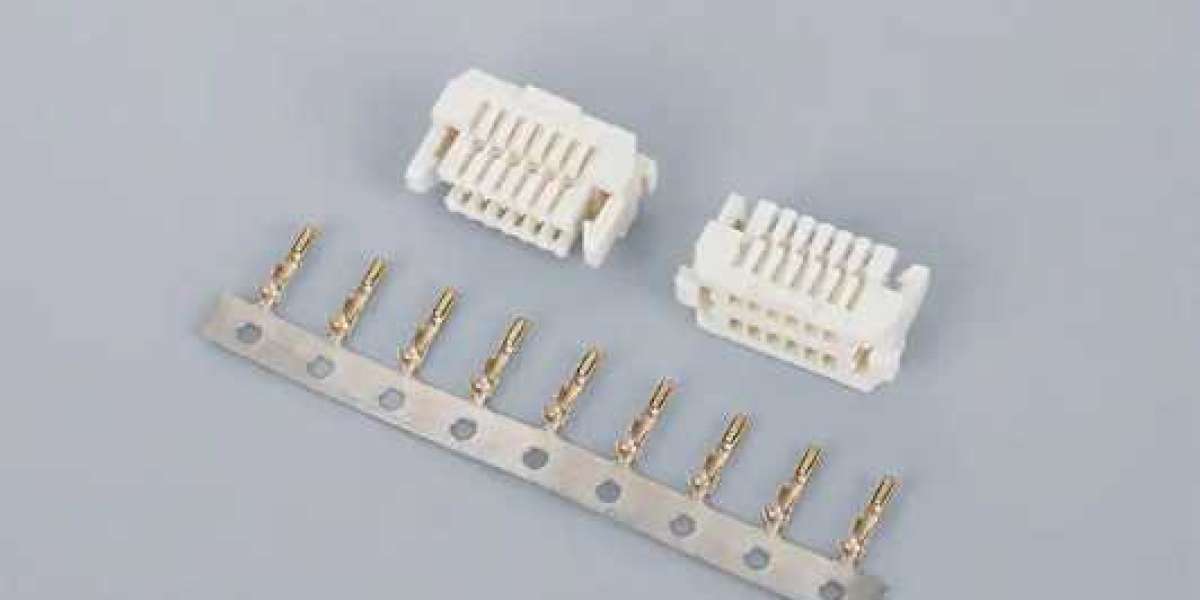

Moreover, loose piece terminals come in various designs, including ring, spade, and butt connectors, each serving different purposes. Their lightweight construction also contributes to their effectiveness in reducing overall system weight, an important consideration in automotive design.

In summary, loose piece terminals offer flexibility, ease of use, and a range of options for electrical connections. Their design allows for quick modifications and repairs, making them an essential component in many electrical applications.