Cement conveyor belts come in various types, each designed to meet specific requirements of the cement production process. The most common types include:

Steel Cord Conveyor Belts: Known for their high tensile strength and durability, these belts are suitable for long-distance transportation and heavy loads. They are resistant to stretching and provide stable operation over long distances.

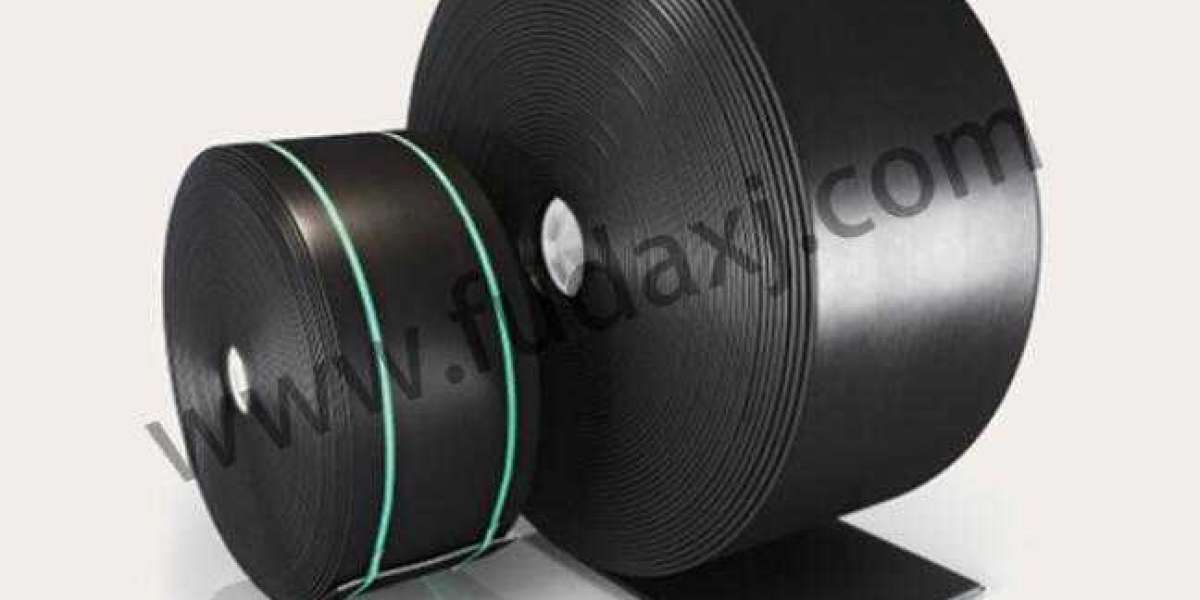

Reinforced Rubber Conveyor Belts: These belts are designed with multiple layers of fabric and rubber, offering flexibility and resistance to abrasion. They are commonly used in applications where the conveyor system needs to navigate through various angles and elevations.

PVC and PU Conveyor Belts: Made from polyvinyl chloride (PVC) or polyurethane (PU), these belts are ideal for applications requiring resistance to chemicals and heat. They are often used in processes involving hot or corrosive materials.

Modular Belts: Constructed from interlocking plastic modules, these belts offer versatility and ease of maintenance. They are suitable for applications requiring frequent belt changes and cleaning.

Each type of conveyor belt is selected based on factors such as load capacity, environmental conditions, and specific handling requirements, ensuring optimal performance in cement manufacturing.