The production of anti-tear conveyor belts requires precision and high-quality materials to meet the demands of industrial use. Reinforcement materials like steel cords or fabric layers are critical for enhancing strength and preventing tears.

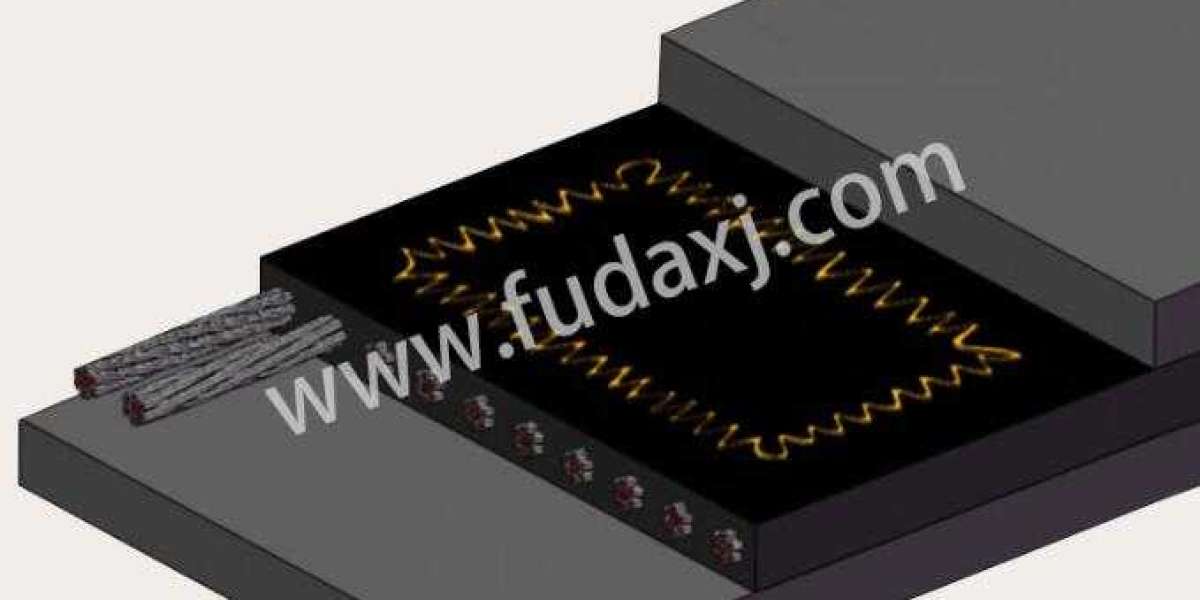

The bonding process between the reinforcement layers and the rubber or polymer surfaces must ensure durability and resistance to delamination. Advanced technologies, such as heat vulcanization, are often employed to create a uniform and robust structure.

Manufacturers also focus on customizing belts for specific applications, such as adjusting thickness, width, or resistance properties. This allows the belts to meet the unique requirements of different industries while maintaining reliability.

Attention to these factors ensures the production of anti-tear conveyor belts that perform effectively in demanding environments.