In the dynamic industrial landscape of the UAE, achieving welding precision is essential for the success and integrity of construction and manufacturing projects. To meet the high demand for top-quality welds, businesses are increasingly adopting advanced technologies, such as horizontal welding carriages. These innovative tools have transformed the welding industry, providing significant improvements in precision and efficiency. At Rockwood Welding Automation, we pride ourselves on offering cutting-edge horizontal welding carriages tailored to meet the diverse needs of various industries in the UAE. Here’s a closer look at how these devices can benefit your business.

Understanding Horizontal Welding Carriages

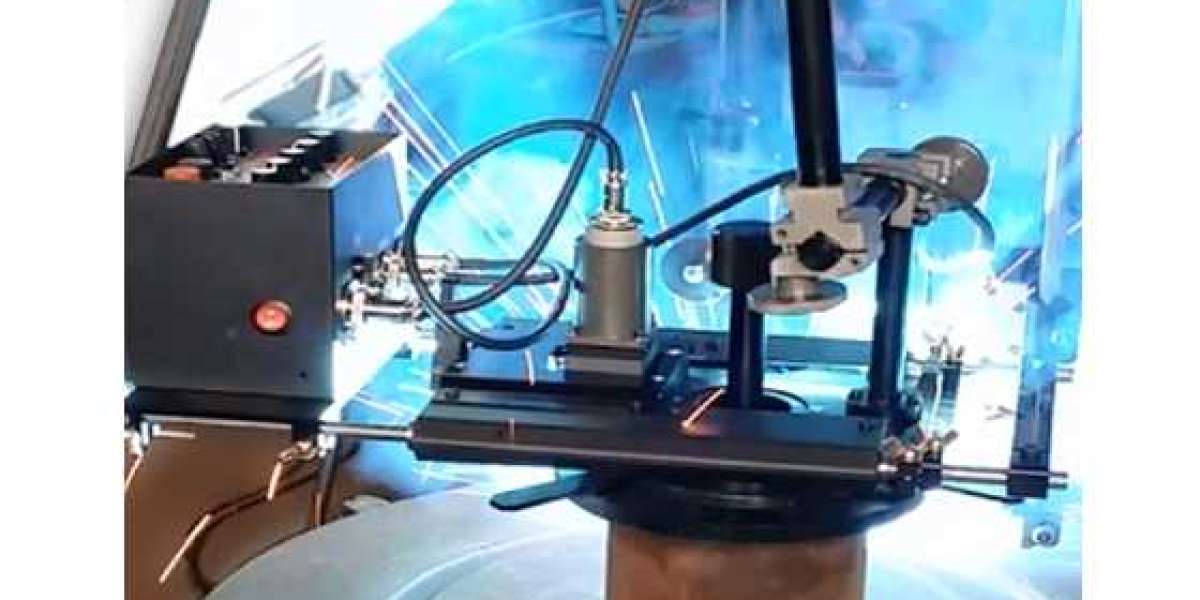

Horizontal welding carriages in UAE are automated or semi-automated devices designed to move along a set path, performing welding tasks with remarkable precision. They come with features that allow for precise control over welding parameters like speed, angle, and direction. These carriages are ideal for horizontal welding applications where consistent weld quality and alignment are crucial.

The Importance of Welding Precision

Precision in welding is critical for several reasons. Firstly, it ensures the structural integrity of welded joints, which is vital in construction and manufacturing applications. Poorly executed welds can lead to weaknesses that may cause structural failures, resulting in costly repairs or even catastrophic accidents. Secondly, precision welding reduces material wastage and rework, contributing to overall cost savings and efficiency. Lastly, high-quality welds enhance the aesthetic appeal of the finished product, which is important in industries such as automotive and aerospace.

Benefits of Using Horizontal Welding Carriages in the UAE

1. Consistent Weld Quality

One of the main benefits of using horizontal welding carriages is the ability to achieve consistent weld quality.

Manual welding is subject to human error, leading to variations in weld quality. Factors such as fatigue, lack of concentration, and inconsistent hand movements can affect the precision of manual welds. In contrast, welding carriages provide a stable platform that ensures uniformity in weld bead placement, penetration, and overall quality. This consistency is especially important in industries that require high standards of weld quality, such as oil and gas, construction, and shipbuilding.

2. Enhanced Precision and Accuracy

Horizontal welding carriages offer precise control over welding parameters, enabling welders to achieve high levels of accuracy. These devices can be programmed to follow specific paths and maintain consistent speeds, angles, and positions throughout the welding process. This precision minimizes the risk of defects, such as undercuts, porosity, and incomplete fusion, which can compromise the integrity of the weld. By ensuring accurate weld placement, welding carriages help improve the overall quality and reliability of welded joints.

3. Increased Efficiency and Productivity

The use of horizontal welding carriages significantly boosts welding efficiency and productivity. Manual welding can be time-consuming and labor-intensive, especially for long welds or repetitive tasks. Welding carriages automate the welding process, reducing the time and effort required to complete welding operations. This increased efficiency allows businesses to meet tight project deadlines and increase their output without compromising on quality. Additionally, the use of welding carriages frees up skilled welders to focus on more complex tasks, further enhancing productivity.

4. Improved Safety

Safety is a paramount concern in the welding industry. Manual welding involves exposure to hazardous conditions, such as intense heat, ultraviolet (UV) radiation, and toxic fumes. Horizontal welding carriages reduce the need for manual intervention, minimizing the risk of burns, eye injuries, and respiratory issues. These devices can be operated remotely, allowing welders to maintain a safe distance from the welding arc and other potential hazards. By enhancing safety, welding carriages contribute to a healthier and more productive work environment.

5. Versatility and Flexibility

Horizontal welding carriages are versatile tools that can be used for a wide range of welding applications. They can accommodate various welding processes, such as MIG, TIG, and flux-cored arc welding, and can be used with different types of materials, including steel, aluminum, and stainless steel. This versatility makes them suitable for diverse industries, from automotive manufacturing to pipeline construction. Furthermore, welding carriages can be easily adjusted and customized to meet specific project requirements, providing flexibility in welding operations.

6. Cost Savings

Investing in horizontal welding carriages can lead to significant cost savings for businesses. The enhanced precision and consistency provided by these devices reduce the need for rework and repairs, minimizing material wastage and associated costs. The increased efficiency and productivity also translate to lower labor costs and faster project completion times. Additionally, the improved safety offered by welding carriages can result in lower insurance premiums and reduced medical expenses related to workplace injuries.

Real-World Applications in the UAE

Horizontal welding carriages have been successfully implemented in various industries across the UAE, demonstrating their effectiveness in improving welding precision and efficiency. In the construction industry, these devices are used for welding steel structures, pipelines, and tanks, ensuring high-quality welds that meet stringent safety standards. In the oil and gas sector, welding carriages play a crucial role in the fabrication and maintenance of pipelines, where precision and reliability are paramount. Additionally, the shipbuilding industry in the UAE has benefited from the use of welding carriages, achieving superior weld quality and faster production times.

Conclusion

The adoption of horizontal welding carriages in the UAE has brought significant improvements to the welding industry. These devices offer numerous benefits, including consistent weld quality, enhanced precision, increased efficiency, improved safety, versatility, and cost savings. Rockwood Welding Automation is committed to providing advanced welding solutions that meet the needs of businesses across various industries. By investing in horizontal welding carriages, businesses in the UAE can achieve higher standards of welding precision and quality, driving their success in a competitive market.