When it comes to restoring the beauty and integrity of metal surfaces, traditional rust removal methods can often fall short. Time-consuming, messy, and sometimes harmful to the material itself, these methods are no longer the go-to for professionals and hobbyists alike. Enter LaserRust, a revolutionary laser rust remover that uses advanced laser technology to remove rust and corrosion effortlessly. If you’re looking for a cleaner, faster, and more efficient way to restore your metal objects, then LaserRust is the answer you’ve been waiting for.

What is LaserRust?

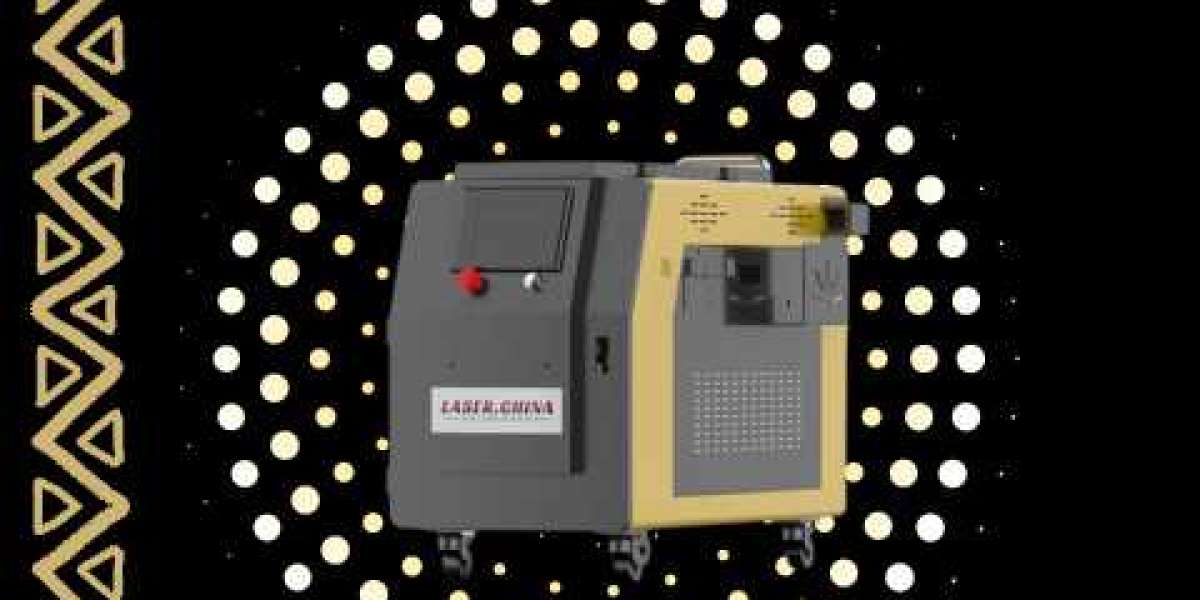

LaserRust is an innovative solution that employs laser technology to effectively remove rust, corrosion, and coatings from metal surfaces without the need for chemicals or abrasive tools. Unlike traditional methods that rely on sandblasting, wire brushing, or harsh chemicals, LaserRust uses a precisely focused laser beam to gently ablate rust and unwanted material. The result is a clean, smooth, and pristine surface ready for further treatment or use.

How LaserRust Works

LaserRust works by emitting high-intensity laser pulses that are carefully controlled to target rust and corrosion on the surface of the metal. The laser energy is absorbed by the rust, causing it to vaporize and disintegrate, leaving behind a clean, unharmed substrate. Since the laser beam is highly concentrated and only interacts with the rust, there is no risk of damaging the underlying metal or creating excessive heat. The process is precise, efficient, and remarkably effective at removing even the most stubborn rust without causing any harm to your project.

One of the most impressive features of LaserRust is its ability to work on various types of metals, including steel, aluminum, copper, and more. Whether you're restoring antique tools, automotive parts, machinery, or marine equipment, LaserRust can be applied to a wide range of industries, making it a versatile addition to your toolkit.

Benefits of LaserRust

Precision Accuracy: The laser can be fine-tuned to focus on specific areas of the metal, providing a level of precision that traditional rust removal methods simply can’t match.

Eco-Friendly: No need for harsh chemicals, solvents, or abrasives, which means less environmental impact and reduced waste. LaserRust is an environmentally friendly solution for rust removal.

No Material Damage: Traditional rust removal can sometimes cause damage to the underlying metal, but LaserRust leaves your metal surfaces intact. The laser technology only targets the rust, preserving the integrity of the material.

Fast and Efficient: LaserRust removes rust at a rapid rate, significantly reducing the time needed for the cleaning process. The precision of the laser means minimal material removal and a smoother, more professional finish.

Minimal Mess: Unlike sandblasting or chemical treatments, LaserRust doesn’t create a mess. There’s no dust, debris, or toxic fumes, making it a cleaner alternative for both indoor and outdoor use.

Ideal Applications

LaserRust is perfect for a variety of applications across industries. It's particularly beneficial for automotive restoration, manufacturing, construction, marine maintenance, and even art conservation. Whether you're tackling large-scale machinery or fine, delicate pieces, LaserRust delivers outstanding results with minimal effort.

Conclusion

If you’re ready to experience the future of laser rust remover, look no further than LaserRust. With its unparalleled precision, eco-friendliness, and efficiency, it’s the perfect tool for anyone looking to restore metal surfaces to their original glory. Say goodbye to rust and hello to a cleaner, better way of maintaining your metal objects. Let LaserRust lead the way in transforming your metal restoration projects.