Transform Your Automotive Components with Precision Casting

Are you looking for a reliable and cost-effective way to produce high-quality automotive components? Look no further than precision casting! Precision casting is a manufacturing process that allows for the production of intricate and detailed automotive components with exceptional accuracy and quality.

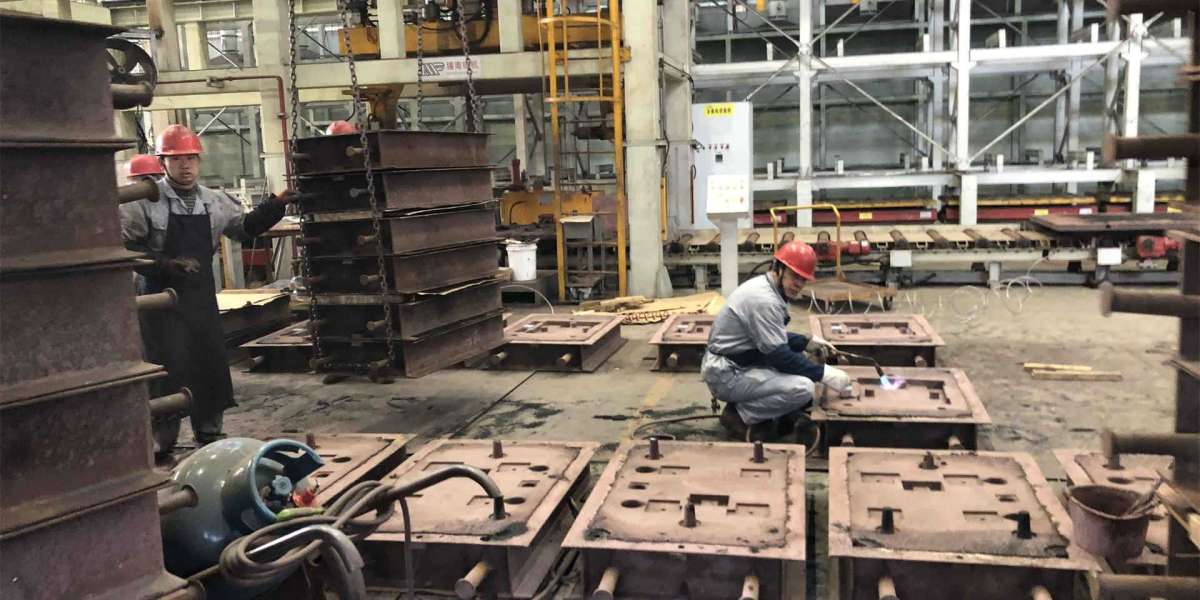

At our automotive casting facility, we specialize in producing a wide range of automotive components, including engine blocks, transmissions, brake systems, and suspension components. Our precision casting process involves pouring molten metal into a mold to create a solid object, allowing for the creation of complex designs and precise dimensions.

Our automotive casting process utilizes state-of-the-art equipment and technology to ensure the highest quality castings. Our team of experienced engineers and technicians work closely with our customers to understand their specific needs and requirements, and to develop customized casting solutions that meet their exact specifications.

Precision casting offers a number of benefits for automotive manufacturers. It allows for the production of intricate and detailed components with high levels of accuracy and quality, reducing the need for secondary machining and finishing processes. Additionally, precision casting can reduce costs and lead times, allowing manufacturers to bring their products to market faster and more efficiently.

Our automotive casting services include mold design and production, casting, finishing, and inspection. We offer a variety of casting materials, including aluminum, brass, bronze, steel, and cast iron, to accommodate different applications and requirements.

Transform your automotive components with precision casting. Contact us today to learn more about our automotive casting services and how we can help you produce high-quality, cost-effective automotive components for your next project.