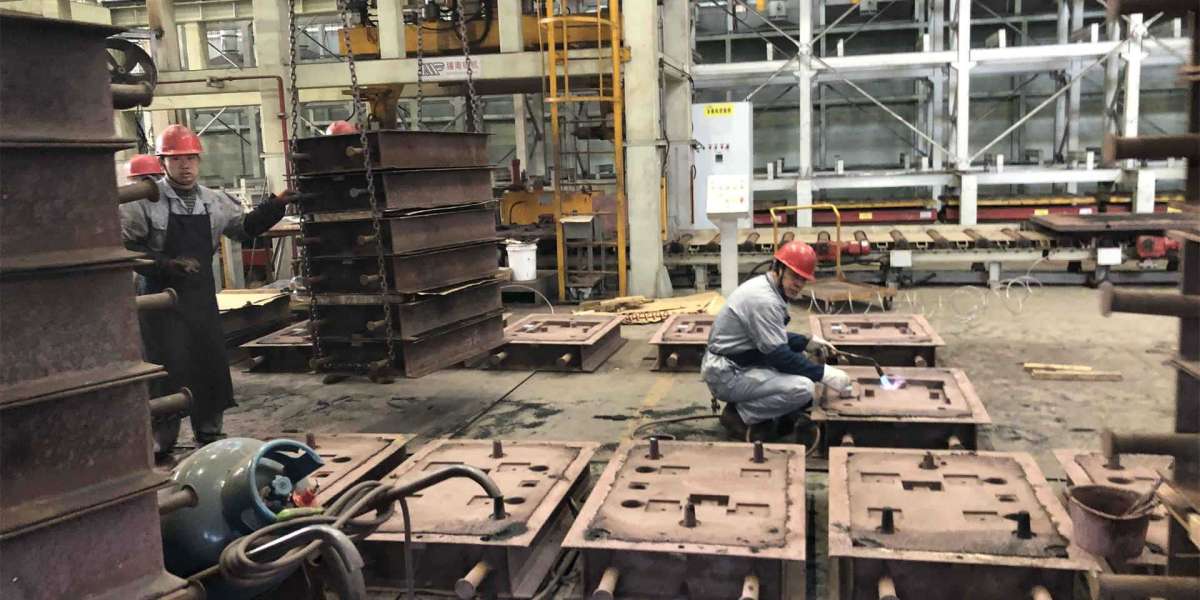

Experience the Versatility and Precision of sand casting

Are you looking for a flexible, cost-effective, and reliable manufacturing process for your next project? Look no further than sand casting. This ancient yet highly advanced technique offers unparalleled versatility and precision, making it the perfect choice for a wide range of applications.

Unmatched Flexibility

sand casting is known for its flexibility in producing parts of various sizes, shapes, and complexities. Whether you need a simple, small component or a large, intricate structure, sand casting can deliver. This versatility makes it an excellent choice for a wide range of industries, including automotive, aerospace, marine, and construction.

Cost-Effective and Efficient

Compared to other casting methods, sand casting is cost-effective and efficient. The molds used in this process are relatively inexpensive to produce and can be easily modified. This makes it an ideal choice for producing low to medium volumes of parts, as well as for prototyping and experimental purposes. With sand casting, you can enjoy shorter lead times and faster production cycles.

High-Quality Results

Despite its cost-effectiveness, sand casting does not compromise on quality. Modern sand casting techniques and materials ensure that parts are produced with high precision and dimensional accuracy. The resulting castings are smooth, strong, and durable, with minimal porosity and defects.

Sustainable Manufacturing

sand casting is also an eco-friendly and sustainable manufacturing process. The sand used in molds can be easily recycled and reused, minimizing waste and environmental impact. This makes it a great choice for businesses looking to adopt sustainable manufacturing practices.

Customizable Solutions

At our foundry, we offer customized sand casting solutions to meet your specific needs. Our experienced team of engineers and technicians will work with you to develop a casting process that optimizes your part design, material selection, and production volumes. We provide comprehensive support, from mold design and casting to finishing and inspection, ensuring that your parts meet the highest standards of quality and performance.

Choose sand casting for your next manufacturing project and experience the combination of flexibility, cost-effectiveness, precision, and sustainability that sets it apart from other manufacturing processes. Contact us today to learn more about how sand casting can benefit your business.