In today’s fast-paced manufacturing and industrial environments, maintaining clean and high-quality metal surfaces is crucial. Traditional cleaning methods, such as abrasive blasting or chemical treatments, can be time-consuming, costly, and harmful to the environment. But thanks to innovations in technology, laser metal cleaner are changing the game. This advanced, efficient, and eco-friendly solution is making metal surface cleaning faster, more effective, and more sustainable. In this blog, we’ll dive into the benefits of laser metal cleaners and why they’re becoming an essential tool in various industries.

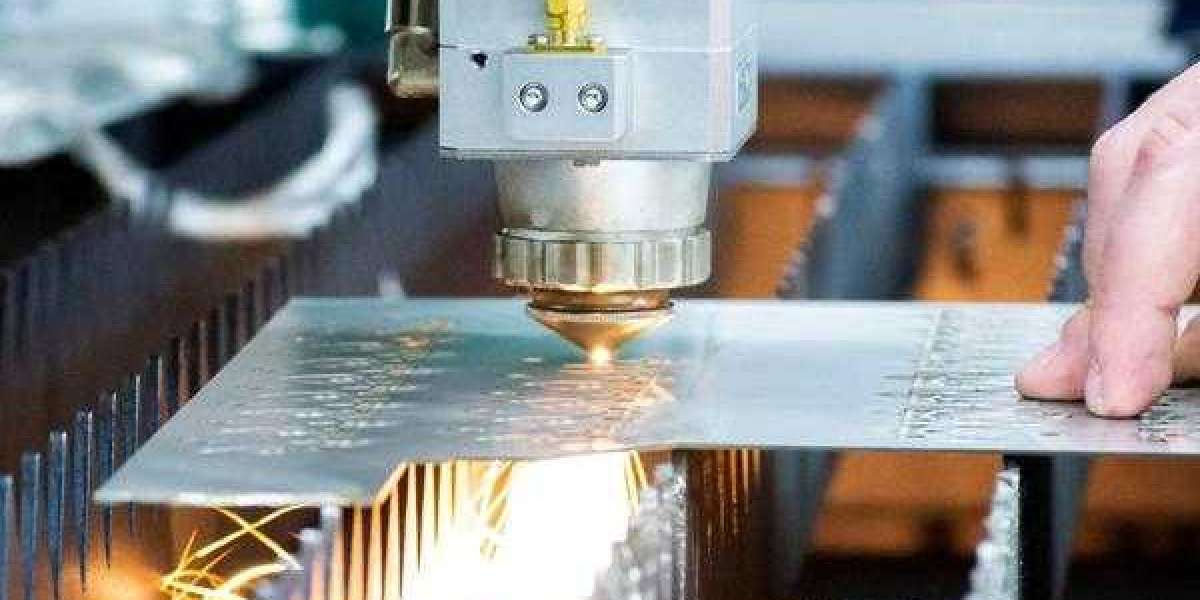

What is a Laser Metal Cleaner? A laser metal cleaner uses high-intensity laser beams to remove contaminants such as rust, oxide, grease, and other pollutants from metal surfaces. By focusing the laser energy on the material, the impurities are vaporized or blown away through a process known as laser ablation. Unlike traditional methods, this process does not require harsh chemicals or abrasive materials, making it both efficient and environmentally friendly.

Laser cleaners are highly effective on a wide range of metals, including steel, aluminum, copper, and titanium. Their versatility makes them suitable for various applications across industries like automotive, aerospace, manufacturing, and more.

The Advantages of Using Laser Metal Cleaners:

Environmentally Friendly: Traditional metal cleaning processes often involve harsh chemicals and abrasive materials, which can be harmful to the environment. Laser metal cleaners, on the other hand, use only light energy, reducing the need for toxic substances. There is no need for water or chemical agents, making this a sustainable choice for companies aiming to reduce their ecological footprint.

Precision and Efficiency: Laser cleaning offers precision that traditional methods can’t match. The laser beam can be controlled to target specific areas, allowing for cleaning without damaging the underlying metal. This precision makes it ideal for intricate parts or components where only certain areas need cleaning. Furthermore, the process is fast, reducing downtime and increasing productivity.

Cost-Effective: While the initial investment in a laser metal cleaner might seem high, the long-term benefits make it a cost-effective solution. Since there are no ongoing costs for chemicals, abrasives, or water, businesses can save money over time. Additionally, the efficiency of the process helps reduce labor costs and minimizes the need for extensive post-cleaning processes.

Improved Surface Quality: Laser metal cleaning helps to maintain the integrity of metal surfaces. It is gentle on materials and does not lead to wear and tear or surface damage, unlike traditional cleaning methods. This results in higher-quality finishes, which is crucial in industries that demand precision and durability.

Minimal Maintenance and Low Operating Costs: Laser cleaners require minimal maintenance compared to conventional methods. There are fewer parts to replace, and no need for the constant supply of consumables like chemicals, sandblasting materials, or abrasive pads. This reduces the overall maintenance burden, making the laser metal cleaner a low-maintenance tool in the long run.

Safe and User-Friendly: Many laser metal cleaners come with integrated safety features that ensure operator safety. Additionally, since the cleaning process is automated, there is less risk of human error. The user-friendly interface of modern laser cleaning machines means that operators can quickly learn how to use the equipment with minimal training.

Applications of Laser Metal Cleaning:

Automotive Industry: Laser cleaners are used to remove rust, paint, and other contaminants from car parts, ensuring they are ready for the next stage of production or assembly. Laser cleaning also plays a role in maintaining the quality of welding seams, helping manufacturers achieve high-quality welds.

Aerospace Industry: Aircraft components require high standards of cleanliness for safety and performance. Laser cleaning is used to remove contaminants from critical parts like turbine blades, ensuring they perform at their best while adhering to safety standards.

Manufacturing: In manufacturing environments, laser metal cleaners are ideal for cleaning various metal parts, from heavy-duty equipment to delicate machinery. They improve the lifespan and performance of the equipment by ensuring that metal surfaces are free from corrosion and other contaminants.

Metal Fabrication: Laser metal cleaning is a perfect fit for metal fabrication, where surface preparation is essential. Laser cleaning can remove oxidation, grease, and other residues, ensuring that the metal is ready for subsequent processes like coating, painting, or welding.

Conclusion: The laser metal cleaner is revolutionizing the way industries approach metal surface cleaning. It offers an environmentally friendly, efficient, and cost-effective solution that enhances precision, productivity, and safety. As more businesses seek to improve their manufacturing processes and reduce environmental impact, laser cleaning technology is likely to become the go-to method for metal surface treatment.

By investing in laser metal cleaning systems, industries can not only meet the growing demand for sustainability but also improve their operations and product quality. Embrace the future of metal cleaning—choose laser metal cleaning today.