In the ever-evolving landscape of industrial cleaning solutions, one technology is emerging as a game-changer: the industrial laser cleaner. This cutting-edge tool is transforming the way industries handle rust, paint, dirt, and other contaminants on metal surfaces. Whether in manufacturing, automotive, or aerospace, laser cleaning offers a cleaner, more efficient, and eco-friendly alternative to traditional methods like sandblasting or chemical treatments. Let’s dive into how industrial laser cleaners are reshaping the cleaning industry and why they’re becoming the go-to solution for industrial cleaning needs.

What is an Industrial Laser Cleaner?

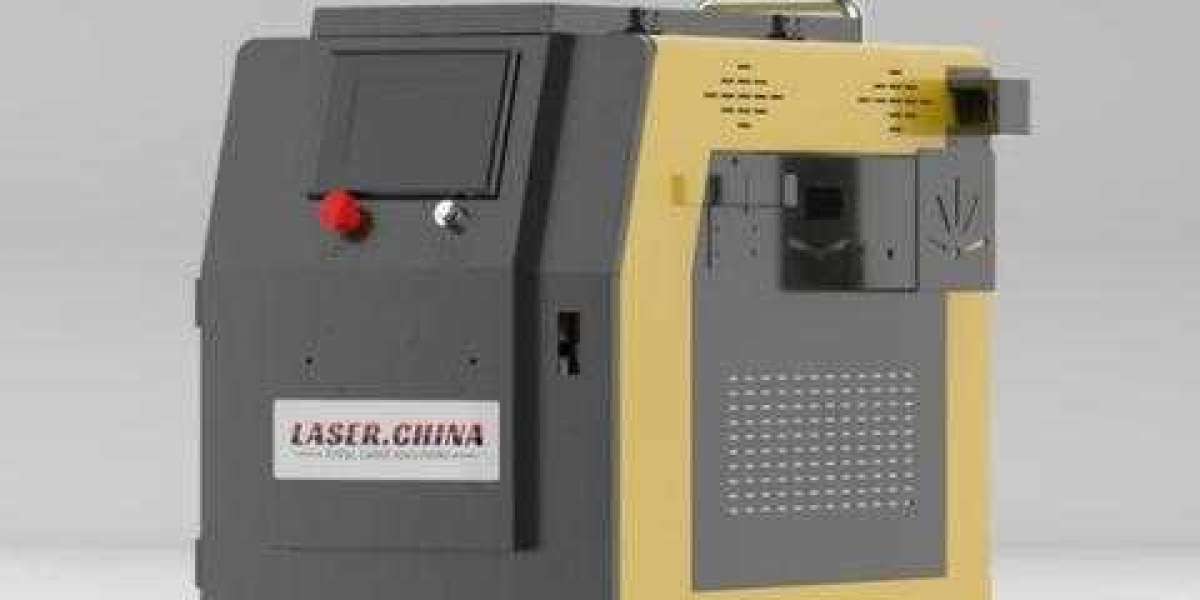

An industrial laser cleaner is a high-tech device that uses the power of laser beams to remove contaminants from metal surfaces without causing damage. The process works by directing a concentrated laser pulse onto the surface, causing a high-energy interaction with contaminants like rust, paint, and grease. This interaction creates a thermal shock that vaporizes or expels unwanted materials, leaving the base metal clean and intact.

Unlike traditional methods, which can involve abrasive materials or harsh chemicals, laser cleaning is highly precise, fast, and environmentally friendly. It’s ideal for surfaces that need delicate cleaning, like intricate machinery parts, turbines, or even historic structures that require a gentle yet effective cleaning solution.

Key Benefits of Industrial Laser Cleaning

1. Precision and Efficiency

Laser cleaning is incredibly precise. The laser can be focused to target specific areas of a surface, ensuring that only contaminants are removed. This precision helps in preserving the integrity of the material underneath, preventing any wear and tear. Additionally, the speed of the laser cleaning process ensures that operations can continue without significant downtime, making it an efficient choice for industries with tight schedules.

2. Eco-Friendly and Safe

One of the most compelling advantages of industrial laser cleaners is their environmental impact—or lack thereof. Traditional cleaning methods often use harmful chemicals or produce hazardous waste, but laser cleaning eliminates these concerns. Since the process only uses light energy, there are no chemicals involved, making it a safer and greener option for industries looking to minimize their environmental footprint.

Moreover, laser cleaning produces minimal waste, and the process does not generate harmful dust or fumes that could pose health risks to workers. This makes it an ideal solution for industries focused on sustainability and worker safety.

3. Cost-Effective

Although industrial laser cleaners may seem like a significant upfront investment, they offer long-term cost savings. The need for consumables like abrasives and chemicals is eliminated, reducing ongoing operational costs. Additionally, because the cleaning process is faster and more efficient, labor costs are also minimized. Over time, this makes laser cleaning a highly cost-effective solution for businesses.

4. Versatility and Adaptability

Industrial laser cleaners are versatile and can be used across various industries, including automotive, aerospace, manufacturing, and even art restoration. They are effective at removing rust, paint, oil, grease, and even graffiti, making them adaptable to a wide range of cleaning tasks. Whether it’s cleaning complex machinery parts, removing coatings from metal surfaces, or restoring historical monuments, laser cleaning offers a precise and reliable solution.

5. Non-Contact Cleaning

Unlike abrasive cleaning methods, which can wear down surfaces over time, laser cleaning is non-contact. The laser does not physically touch the material being cleaned, which means there’s no risk of abrasion or mechanical damage. This is especially important when working with delicate or expensive materials, ensuring that the equipment or objects being cleaned remain in pristine condition.

Applications of Industrial Laser Cleaners

- Automotive Industry: Laser cleaners are used to remove rust and dirt from parts, improving their longevity and performance.

- Aerospace: Laser cleaning is ideal for cleaning turbine blades, engine components, and other delicate aerospace materials.

- Historical Preservation: Laser cleaners are employed in art restoration to gently remove layers of dirt, paint, and corrosion from valuable sculptures and monuments.

- Manufacturing: Laser cleaners effectively remove coatings, oil, and grease from machinery parts, improving their function and extending their lifespan.

Conclusion

As industries continue to prioritize efficiency, safety, and environmental sustainability, the adoption of industrial laser cleaner is set to grow. Offering unmatched precision, eco-friendliness, and versatility, laser cleaning is a solution that meets the demanding needs of modern industry. Whether for manufacturing, aerospace, or even historical preservation, laser cleaning is a powerful tool that promises to transform the way we think about industrial cleaning.

By embracing industrial laser cleaners, businesses can reduce their environmental impact, cut costs, and improve the longevity of their equipment, all while maintaining a high standard of cleanliness and precision.