Enhancing Efficiency in Manufacturing Processes

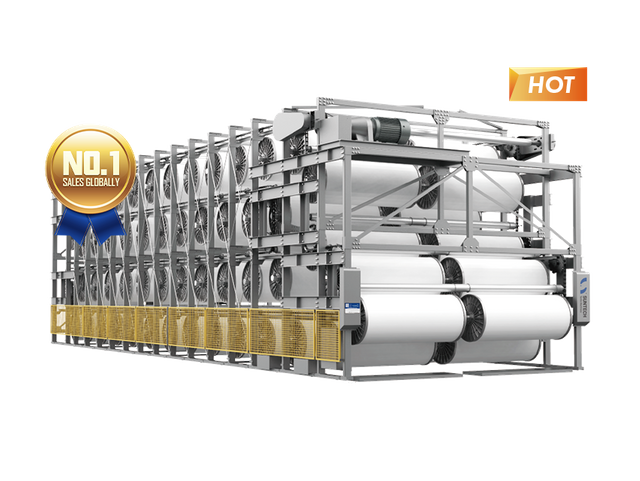

Beam storage importers play a crucial role in the manufacturing industry by optimizing the storage and retrieval of beams used in various production processes. These systems are designed to efficiently organize and manage the inventory of beams, ensuring quick access when needed. By utilizing a beam storage importer, manufacturers can streamline their operations, reduce downtime, and improve overall productivity.

Maximizing Space Utilization

One of the key benefits of implementing a beam storage importer is the ability to maximize space utilization within the manufacturing facility. These systems are designed to store beams vertically, taking advantage of vertical space that would otherwise go unused. By utilizing vertical storage solutions, manufacturers can free up valuable floor space for other operations, ultimately increasing the overall efficiency of the facility.

Ensuring Inventory Accuracy

Inventory accuracy is essential in the manufacturing industry to prevent stockouts, overstock situations, and costly errors. Beam storage importers help maintain accurate inventory records by providing real-time visibility into the quantity and location of beams within the facility. This level of transparency enables manufacturers to make informed decisions regarding inventory management, procurement, and production planning, ultimately leading to cost savings and improved customer satisfaction.

Enhancing Workplace Safety

Workplace safety is a top priority in the manufacturing industry, and beam storage importers can contribute to creating a safer work environment. By storing beams in an organized and secure manner, these systems help reduce the risk of accidents, such as falling objects or tripping hazards. Additionally, beam storage importers can be equipped with safety features, such as sensors and alarms, to further enhance workplace safety and prevent injuries among employees.

In conclusion, the implementation of a beam storage importer in the manufacturing industry is essential for enhancing efficiency, maximizing space utilization, ensuring inventory accuracy, and enhancing workplace safety. By investing in these systems, manufacturers can optimize their operations, reduce costs, and stay competitive in today's fast-paced market.