The logistics robots market is experiencing rapid expansion, driven by a confluence of factors that are reshaping the landscape of supply chain management. As industries seek to enhance efficiency, reduce costs, and meet evolving consumer demands, logistics robots are emerging as a pivotal solution. This article delves into the key drivers fueling the growth of the logistics robots market.

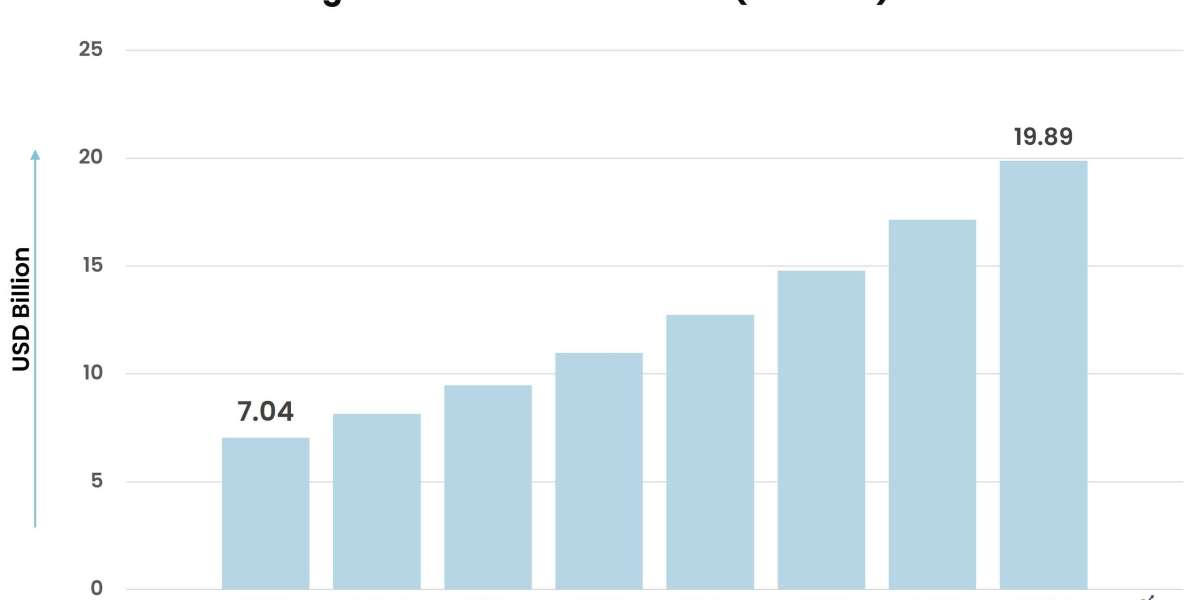

According to Stratview Research, the logistics robots market was estimated at USD 7.04 billion in 2023 and is likely to grow at a CAGR of 16.0% during 2024-2030 to reach USD 19.89 billion in 2030.

- Surge in E-Commerce

The explosive growth of e-commerce is a major catalyst for the logistics robots market. With online shopping becoming increasingly popular, especially during and after the COVID-19 pandemic, there is a heightened demand for efficient order fulfillment and rapid delivery. Logistics robots, including autonomous mobile robots (AMRs) and automated guided vehicles (AGVs), streamline warehouse operations by automating tasks such as picking, sorting, and packing. This automation helps companies handle large volumes of orders quickly and accurately, addressing the growing consumer expectation for fast delivery.

- Labor Shortages and Cost Pressures

Labor shortages in the logistics and warehousing sectors are pushing companies towards automation. Finding skilled workers for repetitive and physically demanding tasks has become challenging and expensive. Logistics robots offer a solution by taking over these tasks, allowing human workers to focus on more complex and value-added activities. Additionally, with rising labor costs, robots provide a cost-effective alternative, reducing the need for large numbers of manual laborers and lowering overall operational expenses.

- Technological Advancements

Advancements in robotics technology and artificial intelligence (AI) are transforming the capabilities of logistics robots. Modern robots are equipped with sophisticated sensors, cameras, and AI algorithms that enable them to navigate complex environments, make real-time decisions, and adapt to changing conditions. These technological improvements enhance the efficiency, accuracy, and flexibility of logistics robots, making them more attractive to companies seeking to modernize their supply chain operations.

- Need for Warehouse Optimization

The growing complexity of global supply chains and the need for optimized warehouse operations are driving the adoption of logistics robots. Companies are increasingly investing in automation to enhance inventory management, reduce errors, and maximize space utilization. Robots help achieve these goals by automating repetitive tasks, improving throughput, and providing real-time data on inventory levels and warehouse performance. This optimization is crucial for meeting the demands of a fast-paced market and maintaining a competitive edge.

- Focus on Safety and Efficiency

Improving workplace safety and operational efficiency is another key driver for the logistics robots market. Robots can handle hazardous materials, work in environments that may be unsafe for humans, and reduce the risk of workplace accidents. By automating high-risk tasks, companies not only ensure safer working conditions but also enhance overall operational efficiency.

Conclusion

The expansion of the logistics robots market is being fueled by the surge in e-commerce, labor shortages, technological advancements, the need for warehouse optimization, and a focus on safety and efficiency. As these drivers continue to evolve, logistics robots will play an increasingly critical role in transforming supply chain operations, offering enhanced productivity and cost savings in a rapidly changing industry.