IMARC Group, a leading market research company, has recently released a report titled “Carbon Fiber Prepreg Market Report by Manufacturing Process (Hot Melt, Solvent Dip), Resin Type (Thermoset, Thermoplastic), Resin (Phenolic, Epoxy, Bismaleimide, Polyimide, Cynate Ester, PEEK, and Others), End Use Industry (Aerospace and Defense, Automotive, Wind Energy, Sports and Recreation, and Others), and Region 2024-2032”. The study provides a detailed analysis of the industry, including the global carbon fiber prepreg market trends, share, size, and industry growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

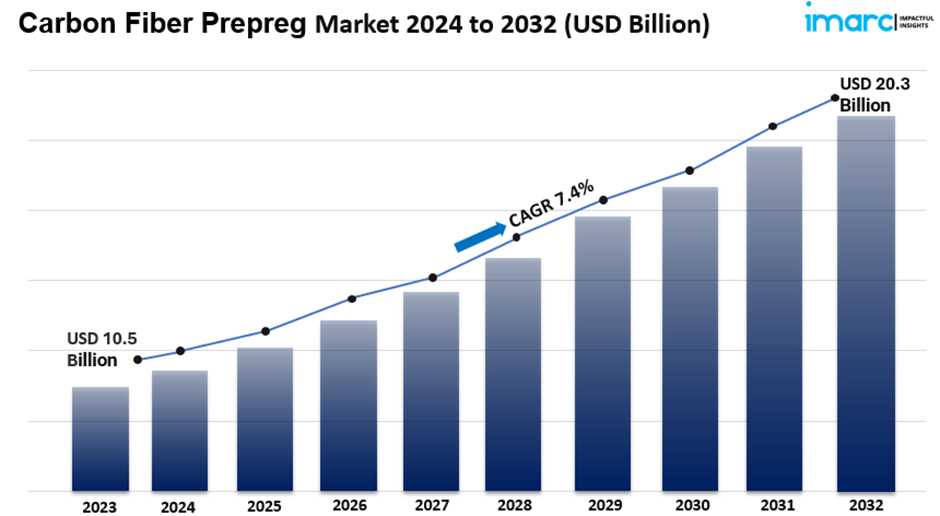

The global carbon fiber prepreg market size reached US$ 10.5 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 20.3 Billion by 2032, exhibiting a growth rate (CAGR) of 7.4% during 2024-2032.

Global Carbon Fiber Prepreg Market Trends:

The increasing adoption of carbon fiber prepregs in the production of wind turbine blades to offer superior strength, stiffness, and reduced weight, enabling the construction of longer and more efficient blades that can capture more wind energy, is enhancing the market growth.

Additionally, the development of cost-effective and efficient methods for recycling carbon fiber composites to address the environmental concerns associated with the disposal of these materials and enhance their sustainability profile is favoring the market growth.

Furthermore, the increasing product utilization in the sports and leisure industries for high-performance equipment, such as bicycles, golf clubs, and hockey sticks, is catalyzing the market growth.

Request to Get the Sample Report:

https://www.imarcgroup.com/carbon-fiber-prepreg-market/requestsample

Factors Affecting the Growth of the Carbon Fiber Prepreg Industry:

- Rapid Technological Advancements in Manufacturing Processes:

The rising innovations in automation and material science that enable the production of high-quality carbon fiber prepregs with enhanced properties, are bolstering the market growth. in line with this, the introduction of advanced techniques, such as automated fiber placement (AFP) and automated tape laying (ATL) that increase production efficiency and consistency, is acting as a growth-inducing factor.

Furthermore, the continuous research and development (RD) in resin systems and curing methods, leading to the creation of prepregs with superior mechanical properties and thermal stability, is expanding the market growth. Besides this, the development of out-of-autoclave (OOA) curing techniques that reduce production costs and improve accessibility for smaller manufacturers, is catalyzing the market growth.

- Growing Product Demand in Aerospace and Defense Sectors:

The growing demand for lightweight and high-strength materials in the aerospace and defense industries, due to the critical need for fuel efficiency, performance, and safety, is positively impacting the market growth. Carbon fiber prepregs offer an excellent strength-to-weight ratio, which is essential for reducing the weight of aircraft and military vehicles without compromising structural integrity. They are extensively used in the production of commercial aircraft, military jets, and space vehicles. Moreover, the growing product reliance in the defense sector for manufacturing unmanned aerial vehicles (UAVs), missile components, and protective gear, is contributing to the market growth.

- Rising Adoption in the Automotive Industry:

The ongoing shift in the automotive industry towards lightweight materials to improve fuel efficiency and reduce emissions is fostering the market growth. Automotive manufacturers are adopting carbon fiber prepregs in the production of high-performance and electric vehicles (EVs).

Moreover, the lightweight nature of carbon fiber composites that contribute to better acceleration, handling, and energy efficiency, which are critical factors in the design and performance of modern vehicles, is catalyzing the market growth.

Additionally, the increasing utilization of carbon fiber prepregs in structural components, body panels, and interior parts to enhances vehicle performance and support the industry's sustainability initiatives, is enhancing the market growth.

Carbon Fiber Prepreg Market Report Segmentation:

By Manufacturing Process:

- Hot Melt

- Solvent Dip

Hot melt represented the largest segment due to its advantages in providing better product quality and reduced environmental impact.

By Resin Type:

- Thermoset

- Thermoplastic

Thermoset accounted for the largest market share owing to its superior mechanical properties and durability, which are essential for high-performance applications.

By Resin:

- Phenolic

- Epoxy

- Bismaleimide

- Polyimide

- Cynate Ester

- PEEK

- Others

Epoxy represented the largest segment due to its excellent adhesion, chemical resistance, and versatility in various industrial applications.

By End Use Industry:

- Aerospace and Defense

- Automotive

- Wind Energy

- Sports and Recreation

- Others

Aerospace and defense accounted for the largest market share, driven by the critical need for lightweight and high-strength materials to enhance fuel efficiency and performance.

Regional Insights:

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa

North America's dominance in the carbon fiber prepreg market is attributed to its advanced aerospace and defense industries, strong presence of automotive manufacturers, and ongoing technological innovations.

Competitive Landscape with Key Players:

The competitive landscape of the carbon fiber prepreg market size has been studied in the report with the detailed profiles of the key players operating in the market.

Some of These Key Players Include:

- Axiom Materials Inc.

- (Kordsa Incorporated)

- Gurit (Tianjin) Composite Material Co. Ltd

- Hexcel Corporation

- Koninklijke Ten Cate B.V.

- (Tennessee Acquisition Holding B.V.)

- Mitsubishi Chemical Holdings Corporation

- Park Aerospace Corp.

- Plastic Reinforcement Fabrics Ltd.

- SGL Carbon SE

- Solvay (Daikin)

- TCR Composites Inc.

- (ATK Launch Systems)

- Teijin Limited

- Toray Industries Inc.

Key Highlights of the Report:

- Market Performance (2018-2023)

- Market Outlook (2024-2032)

- Market Trends

- Market Drivers and Success Factors

- Impact of COVID-19

- Value Chain Analysis

If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact Us:

IMARC Group

134 N 4th St

Brooklyn, NY 11249, USA

Website: imarcgroup.com

Email: sales@imarcgroup.com

Americas: +1-631-791-1145 | Europe Africa: +44-753-713-2163 | Asia: +91-120-433-0800