When it comes to water containment solutions, HDPE pond liners stand out as one of the most reliable and durable materials available. High-Density Polyethylene (HDPE) pond liners are widely used in various applications, including agriculture, aquaculture, landscaping, and industrial projects. These liners provide an effective barrier that prevents water loss and protects the integrity of ponds, reservoirs, and other water bodies. HDPE pond liner manufacturers have developed these products to be resistant to harsh environmental conditions, chemicals, and UV radiation, making them a long-lasting and cost-effective solution for both small and large-scale projects.

In this article, we will explore the importance of HDPE pond liners, their applications, advantages, and how to choose the right pond liner for your needs. We will also discuss the role of pond liner manufacturers and provide tips on how to properly install HDPE liners to maximize their performance.

What is an HDPE Pond Liner?

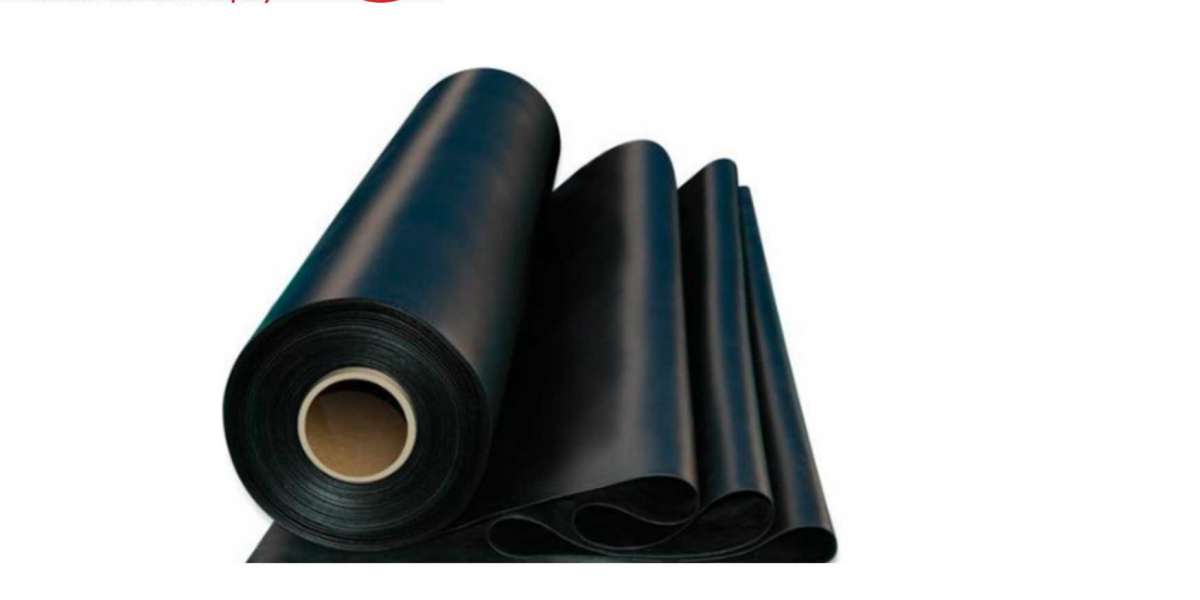

An HDPE pond liner is a synthetic membrane made from high-density polyethylene, a thermoplastic polymer known for its strength, flexibility, and impermeability. These liners are used to create a watertight seal in ponds, reservoirs, and other water containment structures. The key benefit of HDPE pond liners is their ability to prevent water from seeping into the ground, thus ensuring the preservation of water levels and reducing the need for frequent refilling.

HDPE pond liners are available in various thicknesses, typically ranging from 0.5 mm to 2.0 mm, depending on the specific application and site conditions. Thicker liners offer greater durability and resistance to punctures, making them suitable for projects involving heavy machinery or sharp objects.

Applications of HDPE Pond Liners

HDPE pond liners are incredibly versatile and can be used in a wide range of applications, including:

Agricultural Ponds: Farmers often use HDPE liners to create irrigation ponds or water reservoirs. These liners prevent water loss due to seepage, ensuring a consistent water supply for crops.

Fish Farming (Aquaculture): In aquaculture, HDPE pond liners are used to create controlled environments for fish and other aquatic species. The liners prevent contamination from the surrounding soil and provide a stable, clean habitat for aquatic life.

Decorative Ponds and Water Gardens: Landscaping projects often incorporate HDPE liners to create beautiful ponds or water features. The liners ensure that water is retained in the desired area, preventing leakage into the soil.

Landfill Liners and Waste Containment: HDPE liners are also used in landfills and waste containment areas to prevent leachate from contaminating groundwater. Their chemical resistance makes them ideal for these applications.

Industrial and Mining Applications: HDPE liners are used in various industrial applications, such as containment of hazardous liquids, mining tailings, and chemical storage. Their impermeability ensures that harmful substances do not seep into the ground.

Advantages of HDPE Pond Liners

There are several reasons why HDPE pond liner manufacturers recommend HDPE over other types of liners:

Durability: HDPE liners are highly resistant to UV radiation, chemicals, and harsh environmental conditions. This makes them ideal for long-term projects, as they do not degrade easily when exposed to sunlight or fluctuating temperatures.

Cost-Effectiveness: Although HDPE liners may have a higher upfront cost compared to other materials, their longevity and minimal maintenance requirements make them a cost-effective choice over time. They can last for decades without needing replacement.

Flexibility and Customization: HDPE liners are flexible and can be customized to fit ponds of any shape or size. This makes them ideal for irregularly shaped ponds or areas with complex terrain.

Eco-Friendly: HDPE is an environmentally friendly material, as it is non-toxic and recyclable. It is safe for aquatic life and does not release harmful chemicals into the water.

Resistance to Punctures and Tears: HDPE pond liners are incredibly strong and resistant to punctures, tears, and abrasions. This makes them suitable for areas with rocky or uneven ground, where sharp objects could otherwise damage the liner.

Chemical Resistance: HDPE liners are resistant to a wide range of chemicals, including acids, bases, and solvents. This makes them ideal for industrial applications and areas where the liner may come into contact with potentially harmful substances.

Pond Liner Manufacturers: What to Look For

When selecting Pond liner manufacturers, it’s important to choose a reputable supplier who can provide high-quality HDPE liners that meet your project’s specific requirements. Here are a few factors to consider when choosing a manufacturer:

Experience: Look for manufacturers with a proven track record in producing high-quality HDPE liners for a variety of applications. Experienced manufacturers will be able to offer expert guidance on selecting the right liner for your project.

Material Quality: Ensure that the manufacturer uses virgin HDPE material, which is more durable and reliable than recycled materials. Virgin HDPE offers superior performance, especially in terms of UV resistance and longevity.

Customization Options: Choose a manufacturer who can provide liners that are tailored to your project’s dimensions and specifications. Custom-sized liners can save time and reduce waste during installation.

Certifications: Reputable HDPE pond liner manufacturers should have certifications and quality control measures in place to ensure that their products meet industry standards for performance and safety.

Support and Installation Guidance: A good manufacturer will provide support throughout the installation process, including advice on proper handling, storage, and installation techniques. Some manufacturers may also offer installation services to ensure the liner is installed correctly.

Installation of HDPE Pond Liners

Proper installation is critical to the performance and longevity of HDPE pond liners. Follow these steps to ensure a successful installation:

Site Preparation: Clear the pond area of debris, rocks, and sharp objects that could puncture the liner. Smooth the surface to create a flat, even base for the liner.

Liner Placement: Unroll the HDPE liner carefully, avoiding any unnecessary creasing or folding. Make sure the liner covers the entire pond area with enough excess material at the edges to secure it.

Seaming: If your pond requires multiple sheets of HDPE liner, seam them together using thermal fusion or adhesive tape. This will create a watertight seal between the sheets.

Securing the Edges: Anchor the edges of the liner with rocks, soil, or other materials to prevent it from shifting. Ensure that the liner remains securely in place as the pond fills with water.

Filling the Pond: Once the liner is in place, slowly fill the pond with water. Monitor the liner as the water level rises to ensure it remains properly positioned.

Conclusion

HDPE pond liners are a durable, eco-friendly, and cost-effective solution for water containment projects of all sizes. Their strength, flexibility, and resistance to environmental factors make them ideal for applications ranging from agricultural ponds to industrial waste containment. When selecting an HDPE liner, it is crucial to work with reputable pond liner manufacturers who can provide high-quality materials and expert guidance. With proper installation, HDPE pond liners can provide long-lasting water containment and protection for decades to come.

Here Are Three Related For Hdpe pond liner manufacturer

Q1: How long do HDPE pond liners last?

Ans: HDPE pond liners can last 20 to 40 years, depending on environmental conditions and maintenance.

Q2: Can HDPE pond liners be used in aquaculture?

Ans: Yes, HDPE pond liners are widely used in fish farming due to their impermeability and non-toxic nature.

Q3: How do I install an HDPE pond liner?

Ans: Proper site preparation, careful placement, and securing of the edges are key steps in installing an HDPE pond liner.