Introduction

When it comes to lifting and securing big items, selecting the appropriate equipment is critical for safety and efficiency. Webbing slings and chain slings are the two most prevalent alternatives.

While they both perform the same fundamental function—lifting large objects—they have unique characteristics that make them appropriate for diverse jobs.

In this article, we'll look at the fundamental distinctions between webbing and chain slings and how to pick the best one for your needs.

Webbing Slings: What Are They?

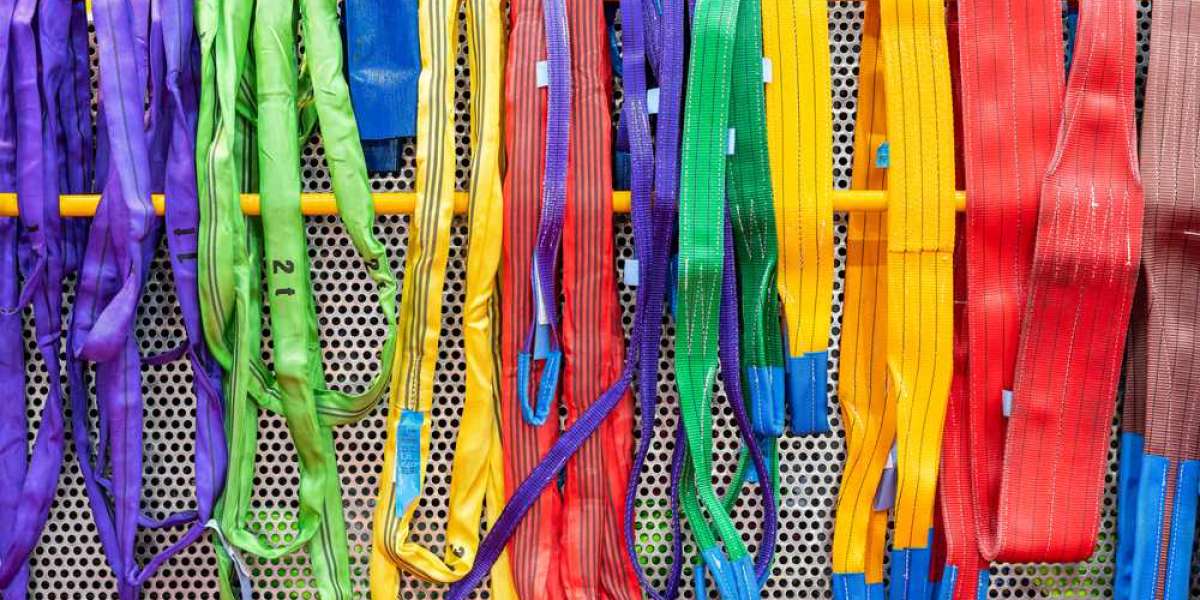

Webbing slings are composed of sturdy synthetic fabrics like polyester or nylon. These slings are generally flat and flexible, making them suitable for lifting objects with delicate surfaces or unusual forms.

A webbing sling supplier offers these slings in a variety of lengths and widths, allowing customers to choose the finest solution for their lifting needs.

Key characteristics of webbing slings:

- Lightweight and Flexible: Webbing slings are lighter and more flexible than chain slings, making them easier to handle and store.

- Non-Abrasive: The webbing's smooth, flat surface eliminates scratches or damage to the weight being lifted, making it ideal for delicate or finished surfaces.

- Corrosion and weather-resistant: Unlike metal chains, webbing slings do not corrode and are less susceptible to water, chemicals, or outside factors.

- Wide Load Distribution: Webbing slings distribute the load more evenly across a larger area, lowering the danger of item damage or point load stress.

What Are Chain Slings?

Chain slings, on the other hand, are constructed using high-strength steel chains. These are used for heavy-duty lifting in harsh areas like construction sites or industrial facilities, where weights can be exceedingly heavy and circumstances are more demanding.

Key Characteristics of Chain Slings:

- Durability: Chain slings are built to endure exceptionally large loads as well as hard working conditions including high temperatures and abrasives.

- Adjustable Length: Chain slings may be readily modified to the desired length by adding or deleting chain links, giving them flexibility in a variety of lifting applications.

- Resistance to Damage: Chain slings are exceptionally durable and less prone to cutting or abrasion, making them ideal for lifting objects with sharp edges or rough surfaces.

- Long Lifespan: Chain slings have a longer service life than webbing slings due to its sturdy design when cared for and inspected properly.

Differences Between Webbing and Chain Slings

- Material:

- Webbing slings are constructed from synthetic materials such as polyester, making them lighter and softer.

- Chain slings are composed of heavy-duty steel chains, which give them more strength and longevity.

- Weight capacity:

- Webbing slings can hoist reasonably heavy weights, up to several tons, depending on the design.

- Chain slings are intended for severe heavy-duty applications and often have a higher load-bearing capability than webbing slings.

- Handling and flexibility:

- Because of their lightweight and flexible nature, webbing slings are simple to use, modify, and store.

- Chain slings are heavier and more stiff, but they provide better flexibility in high-stress situations.

- Surface Protection

- Webbing slings are non-abrasive and perfect for protecting delicate or polished surfaces.

- Chain slings, while more durable, can scrape or damage surfaces, making them unsuitable for lifting delicate things.

- Resistance to environmental factors

- Webbing slings are corrosion resistant and less impacted by chemicals and moisture, making them ideal for outdoor or damp environments.

- Chain slings can rust or corrode over time if exposed to moisture, although they are more resistant to cutting, heat, and abrasion.

How to Select the Ideal Sling for Your Job

The choice between webbing slings and chain slings is determined by a number of criteria, including the kind of load, operating circumstances, and safety standards. Here is a simple guide to help you make the proper decision:

- Consider the Weight of the Load: For lifting huge weights in industrial or construction environments, chain slings are the ideal option. Webbing slings are sufficient for relatively heavy loads, particularly on weak surfaces.

- Consider the Load's Surface: Webbing slings are great for delicate or sensitive loads because to their soft and non-abrasive nature. If the load has sharp edges or is rough, a chain sling would be preferable to save wear and strain on the sling.

- Consider the Working Environment: If the sling will be exposed to water, chemicals, or other corrosive substances, go for a webbing sling. However, chain slings are more durable in severe temperatures or abrasive situations.

- Ease of Use: Webbing slings are lightweight and easy to pack, making them suitable for regular usage. Chain slings are heavier and more stiff, requiring more effort to wield, but they provide greater strength and durability for heavy-duty operations.

- Longevity and Cost: Chain slings may cost more initially, but with regular maintenance, they may last longer, especially in harsh settings. Webbing slings, while less expensive, may need to be changed more frequently if utilized under severe stress circumstances.

Conclusion

Webbing slings and chain slings are both useful lifting methods. The selection on which to employ is mostly determined by your individual lifting demands. Webbing slings are a lightweight, non-abrasive alternative for delicate or moderately heavy items that is easy to use and weather resistant. Chain slings are ideal for lifting big, rough objects because of their longevity, strength, and flexibility.

Working with a reputable webbing sling supplier, regardless of the choice you select, guarantees high-quality, dependable slings that satisfy industry safety requirements. Understanding the distinct advantages of both webbing and chain slings enables you to make the best decision, increasing productivity and safety on the job.

You can pick the appropriate lifting equipment for any activity with confidence if you carefully analyze the kind of load, working environment, and safety needs.