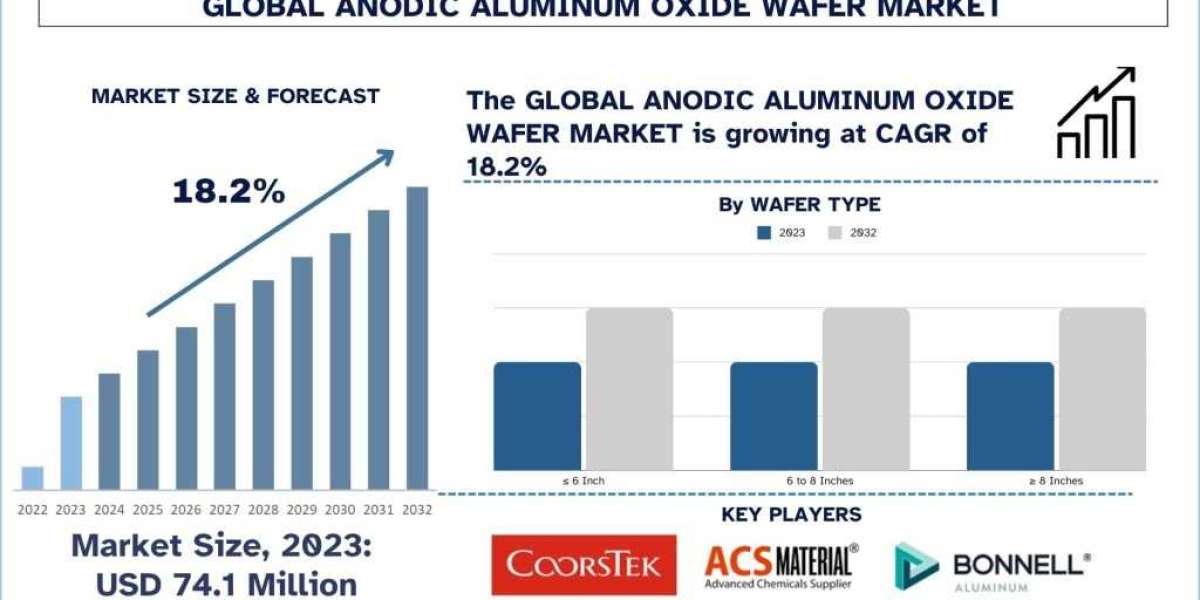

The growth in the renewable energy sector and the expansion of the biotechnology medical devices industry would drive the global scenario of the Anodic Aluminum Oxide Wafer market, according to analysis by Univdatos market Insights. According to their "Anodic Aluminum Oxide Wafer Market" report, the global market was valued at USD 74.1 Million in 2023, with an expected compounded annual growth rate of 18.2% during the forecast period from 2024 – 2032.

The Anodic Aluminum Oxide (AAO) Wafer market provides a unique nanoscale materials architecture that is employed across multiple industries and scientific domains to drive advancements in materials science and nanotechnology. These are increasingly in demand due to the high surface area and tunability of pore sizes of AAO, which have applications ranging from electronics and energy storage to biomedicine. This demand can largely be attributed to the growing focus on research and development activities to provide better offerings due to competition, the global growth of the consumer electronics industry, and rising support from financial institutions for nanotechnology advancements, leading to strong demand for miniature devices.

The market has attracted substantial funding to improve its production capacity and technology further, with a key focus on lowering costs and increasing precision in manufacturing processes. Recent advancements have centered on using AAO wafers in energy-efficient electronics and sophisticated sensor technologies. The expanding spectrum of application areas for AAO wafers has driven businesses to explore their integration into new domains such as healthcare and environmental monitoring, broadening the market's reach. The AAO wafer market dominated by technologically advanced countries such as the US, China, and Japan is expected to grow further due to continuous research and development of advanced chipsets with high-quality transistors nanopore technology plays a mixed role It will also drive growth and increase sales. The use of renewable energy, environmental technologies, and smart devices is expected to remain strong, and policies that encourage innovation and sustainability, such as the U.S. Department of Energy's investment in nanotechnology for renewable clean energy solutions.

Anodic Aluminum Oxide Wafer Overview in APAC

Currently, the Asia-Pacific (APAC) region is set to grow significantly in the Anodic Aluminum Oxide (AAO) Wafer market, thanks to stronger industrial development and an electrifying semiconductor as well as electronics industry. APAC is the largest consumer and manufacturer of electronics comprising Samsung, TSMC, and Sony, amongst others that require AAO wafers due to superior properties that boost the efficiency of microelectronic devices. The high rate of miniaturization of these electronic components as well as the growth in nanotechnology make the use of AAO wafers grow rapidly within this region. These wafers are most suitable for MEMS and other related sensors and other nanotechnology products where the sharpness and stability of the materials used are critical.

Furthermore, APAC is one of the strategic regions for renewable power generation, especially in countries of China, Japan, and South Korea, which are increasingly investing in solar power and energy storage systems. AAO wafers play a vital role in the modern-day production of efficient photovoltaic materials used in the fabrication of advanced solar cells and other green energy storage devices hence enhancing the region's status as a technological powerhouse. Renewable energy sources are the leading force behind the AAO wafer market due to the performance-enhanced capabilities of these materials regarding energy conversion and storage. This trend is backed by government support and policies being put in place across the world with specific country targets for the usage of renewable energy, in turn increasing the demand for AAO wafers.

Thus, the industry of the manufacture of electronics and Renewables, biotechnology, and medical devices in APAC is also a contributing factor to the market of AAO wafers. The region is experiencing sharp improvements in the health sector through improved and developing investment in research and development of new medical technologies. AAO wafers are highly biocompatible and have exacting tolerance, and thus find usage in form biosensors, drug delivery systems, tissue engineering, and many more.

China is the biggest consumer and one of the major hubs for Anodic Aluminum Oxide Wafer.

Being one of the leading countries in the area of manufacturing high-tech products, China has great potential as a supplier of Anodic Aluminum Oxide (AAO) wafers for different industries. Being the largest producer and consumer of electronics, China has a strong industrial background that relies much on materials such as AAO wafers for semiconductors, energy storage, and nanotechnology among others. The sociopolitical pressure to create jobs and promote innovation and technological independence through the up-and-coming innovation cities and government-backed programs fuels the need for superior materials such as AAO wafers due to the rapid urbanization of the country. China’s emphasis on the development of its renewable energy sources, as well as the biotechnology and medical electronics market also adds to the rising prominence of AAO wafers in the region.

Access sample report (including graphs, charts, and figures): https://univdatos.com/get-a-free-sample-form-php/?product_id=65174

Drivers of the AAO Wafer Market in China

- Technological Advancements in Electronics and Semiconductor Industries: Of all the electronics and semiconductor manufacturing industries, China’s electronics and semiconductor industries are among the most developed and expanding industries globally. Various factors have fueled the usage of AAO wafers in the electronics industry lately in a bid to meet the need for miniaturized and high-performing electronic components. Back to top Also, these wafers are very significant in the manufacturing of nanoscale devices, sensors, and microelectric mechanical system MEMS which would be the building blocks of the next generation electronics. Huawei and SMIC are some of the primary industries that are already in the process of adopting the use of AAO wafers in their manufacturing process due to the material’s capability to boost productivity about the competition from world-in industries.

- Government Initiatives and Investments in Renewable Energy: The Chinese government has been putting a lot of money into the production of renewable energy to support its commitment to emission reduction and other forms of green economy. Here, AAO wafers have significant applications in the processes involving the high efficiency of solar cells as well as energy storage equipment. Due to the Chinese government subsidies, research funds, and supportive policy for the renewable energy industry, the usage of AAO wafers has grown rapidly in the renewable energy field. Not only does it promote environmental development in China, but it also increases the need for high-performing materials that enhance the performance of renewable energy technologies.

Conclusion

Therefore, it could be concluded that China and the major region of Asia-Pacific (APAC) are significant growth contributors in the Anodic Aluminum Oxide (AAO) Wafer market due to its strong industrial development, technology adoption, and strategic investments in the high-technology industries. In China, the electronics and semiconductor industries have grown rapidly, and rapidly with the strong support of the government for the development of renewable energy indicates the country’s role in stimulating demand for AAO wafers. Firstly, the APAC region in general with the leading electronics manufacturer counties and the burgeoning biotechnology industry will continue to trend in the use of AAO wafers in applications such as renewable energy, nanotechnology, and medical technology. As these markets progress the need for AAO wafers as the core element in numerous new technologies will expand, further establishing the freedom of the region as a global technological hub.

Contact Us:

UnivDatos Market Insights

Email - contact@univdatos.com

Contact Number - +1 9782263411

Website -www.univdatos.com