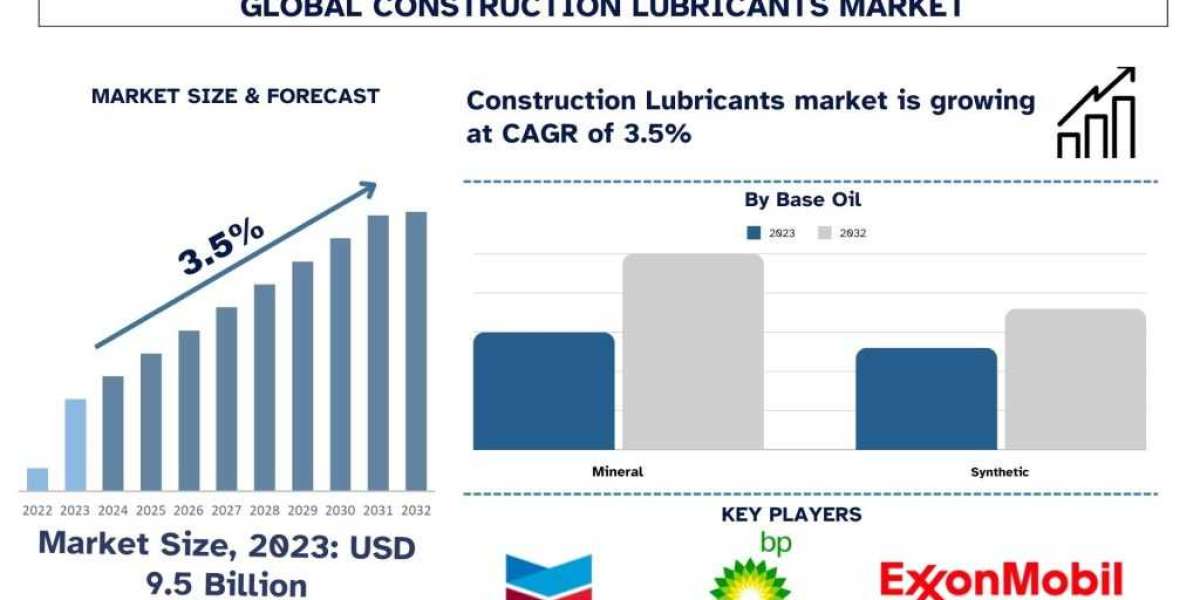

According to a new report by UnivDatos Market Insights, the Construction Lubricants Market is expected to reach USD ~ billion by 2032 by growing at a CAGR of 3.5%. Currently, the construction industry worldwide continues to grow at an incredible rate owing to globalization, development of infrastructure, and construction technology. This growth needs high-efficiency machines and equipment that need efficient maintenance and lubrication to last long and to give efficient service. The construction lubricants ecosystem is another principle factor that contributes to this market worldwide to supply specific products that help in cutting down the wear and tear rate, and friction, and improving the operating conditions of construction equipment in various hard terrains.

Access sample report (including graphs, charts, and figures): – https://univdatos.com/get-a-free-sample-form-php/?product_id=23749

When construction projects are characterized by great complexity and increasingly narrow timeframes, the role of high-quality lubricants has never been so significant. Hydraulic fluids engine oils, and construction lubricants help in improving the function of constructions, lowers chances of breakdown, and hence decrease expenditure on maintenance. In this article, the authors examine the drivers for the construction lubricants market growth, the trends and innovations, useful information, and challenges and opportunities for the construction lubricants market.

Market Overview

The construction lubricants industry has been growing gradually at the global level over the past decade due to the growing demand for construction machinery and equipment. Factors such as the gradual promotion of mechanization in construction processes and corresponding growth in expansive construction projects in the global market have boosted the demand for many types of specialized lubricants for the efficient working of heavy structure equipment.

As well known that the operation of construction equipment takes place under very severe conditions be it in high temperatures or under heavy loads lubricants act as vital in maintaining the efficiency of this equipment. Increased focus on minimizing time spent on machines’ breakdowns and the costs of maintenance has also contributed to application demand for high-performance lubricants.

The market has been classified based on the type of lubricant it offers, namely hydraulic fluids, engine oils, transmission fluids, gear oils, and grease. All these lubricants are developed to tackle various challenges that construction machinery experience when in operation under difficult circumstances. Hydraulic fluids are used to perform hydraulic systems while engine oils offer protection to engine parts against abrasion and heat.

The Construction Lubricants Market: Current—Trends and Innovations

Some of the new directions and trends that are visible in the global construction lubricants market include the following:

Advanced Synthetic Lubricants

This entails developing integrated construction lubricant solutions that incorporate modern synthetic base stocks in place of the normally used conventional oils. Compared to mineral-based oils, synthetic lubricants are good thermal stables, have high viscosity, and are resistant to oxidation and wear. These lubricants are also harder to get past their peak for them to be suitable for construction equipment that works in tough conditions of temperature.

Synthetic lubricants also have a greater duration of performance than regular lubricants, this eliminates frequent oiling and thus less equipment downtime. As construction companies look forward to improving their productivity and cutting costs, there will be an increased market for synthetic lubricants.

Special Packaging Lubricants and Sustainable and Eco –-Friendly Lubricants

The rising concern towards climatic change around the world has forced manufacturers in the construction industry to come up with environmentally friendly lubricants. The sources of lubricants are renewable vegetable oils and these types of lubricants have developed interest as green lubricants in recent times. These lubricants are environmentally friendly in that they are non-hazardous for use within fragile ecosystems such as construction sites in water sources and other conserved regions.

Moreover, increased concern for compliance with state and corporate and security legislation requirements also promotes the reduction of adhesion, and energy savings through the use of environmentally friendly lubricants by construction companies. It will also be seen to fuel the advance of more advanced and efficient sustainable lubrication products for cars.

Nanotechnology in Lubricants

Over the years, it has become apparent that the application of nanotechnology can improve the performance of construction lubricants at a conspicuous level. Beneficial attributes of the dispersed phase include enhanced thermal conductivity of the base oil, reduction of friction, and enhanced resistance of the nanofluid to wear. This leads to increasing the durability of the machinery components and enhanced efficiency of the flow components.

The laminar-reinforced nanoparticles lubricants are especially suited to heavy construction equipment transport systems which are characterized by excessively high operating conditions and continual stress. It is then for this reason that with increasing research done about nanotechnology, we are likely to come across a wider application in the construction industry of nano-enhanced lubrication.

Digital, Business Processes and Predictive Maintenance

This is another important trend affecting the lubricants market – the gradual introduction of digital technologies in construction. By using IoT and data analysis, predictive maintenance enshrines the performance of construction machinery to track in real-time that when it needs maintenance or lubrication. This lowers the possibility of failure of the equipment and cuts on the possible times hence saving a lot of costs.

Self-applied lubrication systems, which apply lubricants using real-time information regarding machines, are now being adopted on construction plant equipment. These systems make it possible for machinery to be optimally always lubed, thereby decreasing breakages as far as possible. A rise in the utilization of smart lubrication and predictive maintenance systems should act as the major catalyst for the requirement for sophisticated lubricants compatible with smart technologies.

Uses of Construction Lubricants

Construction lubricants have relevance in serving different construction machinery and construction equipment. Some of the key applications include:

Hydraulic Systems

Hydraulic fluids are used for a pressure requirement in hydraulic systems, which is specifically used in construction machines like excavators, bulldozers cranes, etc. These fluids have to be thermally stable and resist wear and oxidation so as to allow the hydraulic systems to work while under high loads.

Engines

Engine oils are employed in a way that they can reduce the wear, overheating, and corrosion of the parts of the engine. In construction machinery, there are high operating temperatures and high loads on the engines and thus require high-performance lubricants.

Transmission Systems

Transmission fluids are used for the lubrication of gear systems in construction equipment. These lubricants need to have good shear stability and viscosity control in order to withstand the conditions that are likely to be exerted on parts of the transmission during periods of high usage.

Greasing of Moving Parts

It is utilized to reduce friction in between construction equipment that utilizes bearings and joints that are frequently under force and so prone to wear. To reduce the wearing rates and to safeguard components from corrosion, high-performance greases are required to improve the operating durability of equipment.

Regional Insights

The global construction lubricants market is growing across multiple regions, with each region displaying distinct characteristics:

North America

The North American market is developed due to the better construction industry in this region and the higher utilization of technologized mining equipment. The U.S is the leading consumer of construction lubricants because of its emphasis on infrastructure and the usage of modern innovative technologies in construction.

Asia Pacific

The construction lubricants market is expected to grow most rapidly in Asia Pacific due to increased urbanization, industrialization, and extensive construction projects across countries such as China, India, and Southeast Asian countries. The rising spree in construction activities across the region is the key growth driver that new institutions are establishing for high-performance lubricants.

Europe

In Europe for instance the aspect of sustainability and Environmental standards are forcing the market to go Green and look for Eco-friendly lubricants. The region also contains several of the world’s top lubricant makers who are already engaged in research and development to create new forms of lubrication solutions.

Click here to view the Report Description TOC – https://univdatos.com/report/construction-lubricants-market/

Challenges and Opportunities

However, while there are growth prospects in the market, there is also a consideration of several challenges facing the construction lubricants market at the global level. This relationship is also subject to its existing raw material whereby the cost of production fluctuates with changes in the price of raw materials specifically petroleum base lubricant. In addition, the current legislative attempts at environmental control of the exhaust emission of conventional lubricating oils are putting pressure on firms to produce eco-friendly products.

Nevertheless, all these challenges offer prospects for development and peculiarities of learning. There is a new need for improved and more sustainable lubricants and lubrication systems due to the increasing digitalization in the construction industry. There is greater scope for innovation for firms that are willing to assume the costs of research and development for high-performance lubricants that are also eco-friendly, thus implying the ability to achieve a competitive advantage in the market.

Conclusion :

Over the next several years, construction lubricants are expected to experience steady growth on account of the rising need for high-performance construction equipment, the latest developments in construction lubricants, and the industry’s transformation towards sustainable solutions. It shows trends like synthetic lubes, nanotech revolution, or smart lubes systems that are on the horizon which would open up a new horizon for growth in the market. Lubricants will always be relevant as an aspect of construction because as construction equipment continues to develop the level of lubrication that is necessary to guarantee optimum performance will ultimately remain relevant in construction

Related Report

Biobased Leather Market: Current Analysis and Forecast (2024-2032)

Polybutylene Adipate Terephthalate Market: Current Analysis and Forecast (2024-2032)

Betaine Market: Current Analysis and Forecast (2024-2032)

Phase Change Material Market: Current Analysis and Forecast (2024-2032)

Maleic Anhydride Market: Current Analysis and Forecast (2024-2032

Contact Us:

UnivDatos Market Insights

Email - contact@univdatos.com

Contact Number - +1 9782263411

Website - https://univdatos.com/