Nitrile rubber (NBR), also known as Buna-N or acrylonitrile butadiene rubber, is a synthetic rubber widely used in various industries due to its excellent resistance to oils, fuels, and chemicals. Understanding the nitrile rubber price trend analysis is essential for manufacturers, suppliers, and industry stakeholders to make informed decisions. This article provides a comprehensive analysis of nitrile rubber prices, examining the factors influencing these trends, regional variations, and future market forecasts.

Market Overview

Nitrile rubber is produced through the copolymerization of acrylonitrile and butadiene. Its price is influenced by supply and demand dynamics, raw material availability, production costs, technological advancements, and geopolitical events. Major markets for nitrile rubber include North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa.

Enquire For Regular Prices: https://www.procurementresource.com/resource-center/nitrile-rubber-price-trends/pricerequest

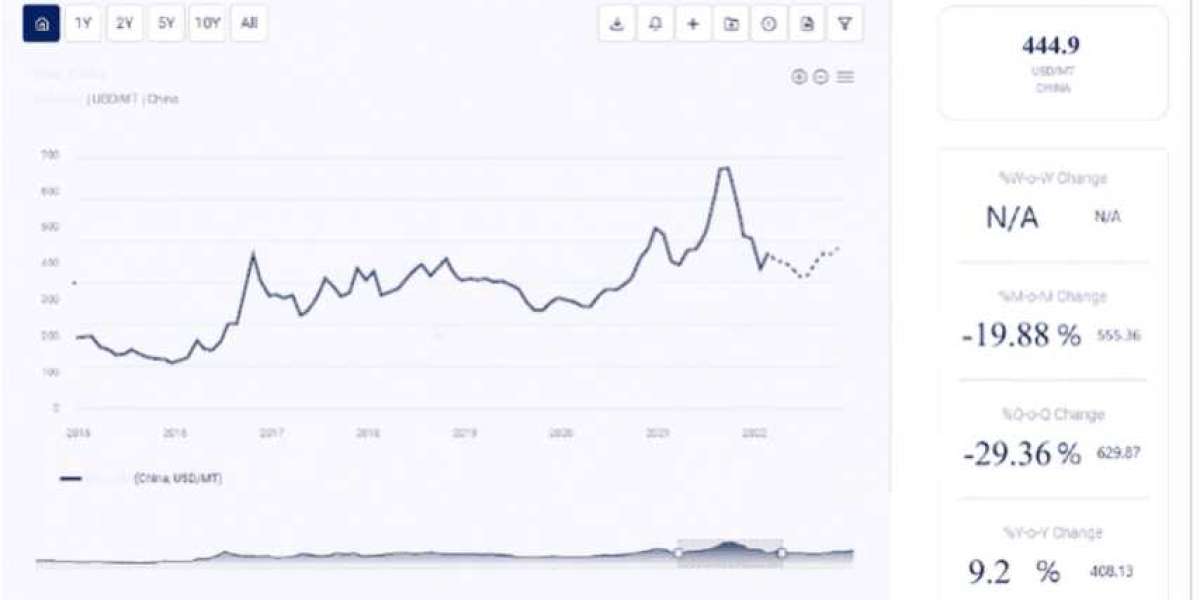

Current Nitrile Rubber Price Trends

The nitrile rubber market has shown variability due to various market dynamics. Several key factors contribute to these price trends:

Supply and Demand Dynamics: The primary driver of nitrile rubber prices is the balance between supply and demand. High demand from the automotive, healthcare, and industrial sectors continues to push prices upward. Any disruptions in supply, such as raw material shortages or production halts, can further impact prices.

Raw Material Availability: The availability and price of acrylonitrile and butadiene, the primary raw materials for producing nitrile rubber, directly affect production costs and, consequently, prices. Fluctuations in raw material prices due to environmental factors or market demand can lead to variability in nitrile rubber prices.

Production Costs: The cost of producing nitrile rubber, including labor, energy, and transportation, plays a crucial role in determining its market price. Advances in production technology can help reduce costs and stabilize prices.

Technological Advancements: Innovations in the production and processing of nitrile rubber can impact supply dynamics. Technological improvements that enhance efficiency or yield can lead to changes in production costs and market prices.

Geopolitical Events: Political stability in major nitrile rubber-producing regions significantly affects supply chains. Geopolitical tensions or regulatory changes can lead to supply disruptions and price volatility.

Environmental Regulations: Stricter environmental regulations related to the production of raw materials for nitrile rubber can impact supply and costs. Compliance with these regulations may require investments in cleaner technologies, affecting production costs and prices.

Regional Price Variations

Nitrile rubber prices vary across different regions due to local production capacities, demand levels, and regulatory environments. Here is a regional analysis of nitrile rubber prices:

North America: In the US and Canada, nitrile rubber prices are influenced by demand from the automotive and healthcare sectors. Regional factors such as economic policies, industrial activity, and local demand also play a role.

Europe: European nitrile rubber prices are influenced by economic conditions within the Eurozone, environmental regulations, and demand from the automotive and industrial sectors. Countries like Germany and France play significant roles in the regional market.

Asia-Pacific: The Asia-Pacific region, particularly China and India, is a significant market for nitrile rubber due to high industrial demand. Prices in this region are driven by rapid industrialization, infrastructure projects, and technological advancements.

Latin America: As a growing producer of nitrile rubber, Latin America’s prices are influenced by local production, economic stability, and regional demand. Countries like Brazil are becoming increasingly important in the global supply chain.

Middle East and Africa: In these regions, local demand for nitrile rubber in various industries and regional economic conditions influence prices. Political stability and regulatory environments also play crucial roles.

Factors Influencing Nitrile Rubber Prices

Several factors play a crucial role in determining nitrile rubber prices:

Global Economic Health: The overall health of the global economy influences investor behavior and demand for industrial materials like nitrile rubber. Economic growth in major economies typically drives up nitrile rubber prices due to increased industrial activity.

Supply and Demand Dynamics: The balance between nitrile rubber production (supply) and consumer demand for automotive, healthcare, and industrial applications significantly affects prices. High demand and limited supply lead to higher prices.

Currency Fluctuations: Changes in currency values, particularly the US dollar, impact nitrile rubber prices. A weaker dollar typically leads to higher nitrile rubber prices as it becomes cheaper for foreign buyers.

Technological Advancements: Innovations in nitrile rubber production and processing technologies can impact supply and demand dynamics. Advances that improve production efficiency or create new market opportunities can influence price trends.

Geopolitical Events: Events such as wars, political instability, and international conflicts can disrupt supply chains, leading to price volatility. Stability in major nitrile rubber-producing regions is crucial for maintaining steady supply and prices.

Environmental Regulations: Environmental regulations and sustainability initiatives can impact production processes and costs. Compliance with these regulations may require investments in cleaner technologies, affecting production costs and prices.

Applications of Nitrile Rubber

Understanding the diverse applications of nitrile rubber can provide insights into the factors driving its demand and, consequently, its price. Some of the primary applications include:

Automotive Industry: Nitrile rubber is extensively used in the automotive industry for making fuel and oil handling hoses, seals, and grommets due to its resistance to oils and fuels. The demand from the automotive industry significantly drives the market.

Healthcare: Nitrile rubber is used in the production of medical gloves, tubing, and other medical devices due to its resistance to chemicals and punctures. The demand from the healthcare sector impacts the market dynamics.

Industrial Applications: Nitrile rubber is used in various industrial applications, including the production of hoses, seals, and gaskets. The demand from the industrial sector influences the market.

Consumer Goods: Nitrile rubber is used in consumer goods such as gloves, adhesives, and sealants. The demand from the consumer goods sector impacts the market.

Aerospace: Nitrile rubber is used in aerospace applications for seals and gaskets due to its durability and elasticity. The demand from the aerospace industry impacts the market.

Oil and Gas Industry: Nitrile rubber is used in the oil and gas industry for making hoses and seals that can withstand harsh chemical environments. The demand from this industry influences the market.

Future Price Forecast

The outlook for nitrile rubber prices remains optimistic due to several factors:

Sustained Demand from Various Industries: The push for durable and chemical-resistant materials in various industries is expected to keep nitrile rubber demand high. These industries require significant amounts of nitrile rubber, supporting long-term price increases.

Economic Growth in Developing Regions: Continued industrialization and urbanization in countries like China and India will drive sustained demand for nitrile rubber.

Supply Constraints: Potential supply constraints from major nitrile rubber-producing regions due to environmental regulations or geopolitical issues could push prices higher.

Technological Innovations: Advances in production technology and the development of new applications for nitrile rubber could drive market growth. Innovations that enhance production efficiency or create new market opportunities may help stabilize or reduce prices.

Global Economic Conditions: Ongoing global economic recovery efforts and infrastructure investments post-COVID-19 are likely to support higher nitrile rubber prices.

Sustainable and Ethical Production: Increasing focus on sustainable and ethical production practices may impact nitrile rubber supply and, consequently, prices. Stricter regulations and higher production costs could lead to higher prices.

Conclusion

The nitrile rubber market is influenced by a complex interplay of factors, including supply and demand dynamics, economic conditions, technological advancements, and geopolitical events. The price of nitrile rubber is driven by strong demand from various sectors and potential supply constraints. Investors and stakeholders should closely monitor these trends to make informed decisions and optimize their strategies.

Understanding the key factors influencing nitrile rubber prices and staying abreast of market developments can help businesses navigate the dynamic landscape and achieve long-term success. As the world continues to move towards more sustainable and technologically advanced solutions, the demand for nitrile rubber is expected to remain strong, supporting stable or increasing prices in the long term.