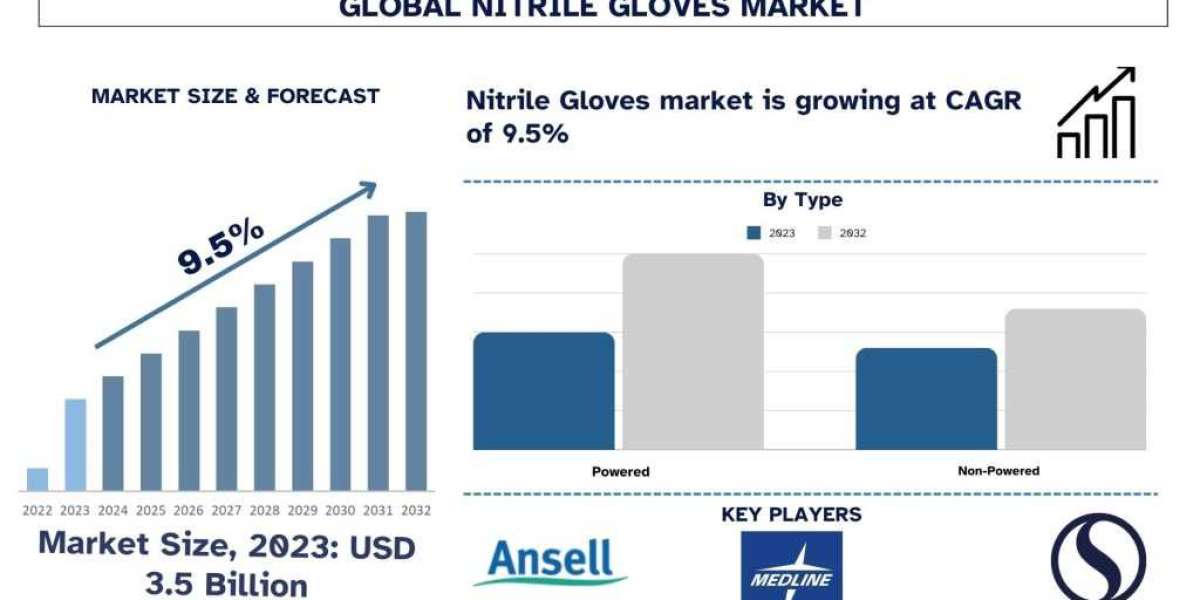

According to a new report by UnivDatos Market Insights, the Nitrile Gloves Market is expected to reach USD billion by 2032 by growing at a CAGR of 9.5%.

Introduction

Nitrile rubber, or nitrile-butadiene rubber (NBR) is a copolymer based on acrylonitrile and butadiene is a synthetic rubber. Today is well-known for its superior ability to withstand oils, fuels, chemicals, and elevated and low temperatures, making it an invaluable material in many industries. Its stability and adaptability have made it suitable for Hornos’ various uses including in the automotive, industrial, health/AIDS product, and consumer product industries. Due to the rising importance of safety features in industries and the requirement for products with competent resistance to different conditions, the nitrile rubber market has progressed considerably in the last few years.

Consequently, to give the reader a broad perspective of the nitrile rubber market, this article explores its growth fundamentals, emerging trends, challenges, and the prospects for further international growth.

Market Overview

The market for nitrile rubber has expanded steadily over the years as the material’s versatility and uses have become known to manufacturers and consumers globally coupled with the growing requirement for oil-resistant rubber products. The market is majorly growth-driven by the automotive sector where nitrile rubber is fit for seals, gaskets, hoses, and O-rings due to its usable performance at high heat or oil-leaching environments. Moreover, the derivatives of nitrile rubber have also been observed to have increased demand in the healthcare segment particularly during the Covid-19 crisis because nitrile gloves are more puncture and chemical/biological resistant.

Nitrile rubber is widely used in industries where high-performance elastomers are used. Starting from the oil and gas industry to healthcare, specifically construction to the automotive industry there is always a continuous demand for this product. However, the market is subjected to other factors including the availability of raw materials, the emergence of new technologies, and the increasing culture of environmental conservation.

Primary forces influencing the demand patterns in the Nitrile Rubber Market

Automotive Industry Demand

However, the major player that is fuelling the demand for the nitrile rubber market globally is the automotive industry. Acrylonitrile rubber has many applications in the automobile industry whenever there is a need for oil, fuel, and: temperature-resistant parts. Components such as gaskets, seals, and hoses are normally made from nitrile rubber due to their elasticity to ensure proper working. Thus, the so-needed nitrile rubber stays relevant as the automotive industry evolves by the demand and new technologies such as EVs automotives. Furthermore, the changes in the automotive industry, particularly the shift to using electric vehicles, impose varying heat and other performance demands on rubber, which is why nitrile rubber is a critical material in the modern automobile industry.

Industrial Applications

The ability of nitrile rubber to withstand chemically corrosive and fuel and oil-laden environments makes it practically essential in industrial machines and apparatus. It is applied in the manufacture of seals, gaskets, and hoses which ensure effective functionality in enterprises such as petroleum and natural gas, chemical production, and engineering machinery. There is upbeat demand for nitrile rubber in these sectors due to the need for serviceable and long-lasting material in these industries most especially in Asia-Pacific and the Middle East where industrial growth is constantly growing.

Anyway, nitrile rubber has found new applications in manufacturing protective clothing and accessories including shoes, gloves, and protective garments for industrial workers. More industry segments emphasize employee safety and outcomes of operations, so the need for nitrile rubber-based safety items will grow.

Healthcare Sector Growth

Healthcare is another factor within the market for nitrile rubber especially because of its usage in the manufacturing of medical gloves. Today nitrile gloves are used widely in medical facilities because they are chemically more resistant, and more cut-resistant than normal latex gloves, and because of their non-allergic nature, they have replaced the medical-ordinary-latex gloves. The outbreak of the COVID-19 pandemic has further augmented the adoption of nitrile gloves and the diversification of the global nitrile rubber supply chain to meet the current world demands that may be occasioned by modern epidemics.

Other than gloves, nitrile rubber is used in medical equipment and pharmaceutical packaging which makes it a strong ground in health facilities. With the world’s population advancing and the availability of healthcare services increasing, the market for nitrile rubber in this sector tends to continue rising.

Latest Trends in the Nitrile Rubber Market

Eco-friendly and Sustainable Approach

With environmental issues arising in the recent past, companies are incorporating strategies that will help them cut costs on greenhouse gases and embrace sustainable materials. This trend is currently being reflected in the nitrile rubber industry since manufacturers continue to seek out ways how they can create better nitrile rubber products that are environmentally friendly, and which guarantee a high level of performance of the material. Green chemical engineering and biopolymers have been deemed as near solutions to the environmental challenges of nitrile rubber synthesis.

Furthermore, the recycling of nitrile rubber products is being considered in automotive and industrial applications since industries have begun to adapt to recycling systems for products that have circular economies. The future of the market depends on the technologies for recycling nitrile rubber without upgrading its performance to a higher rank.

Current Technology Trends of Nitrile Rubber Manufacturing

Recent developments in the areas of polymerization and fabrication practices put into practice improvements in the nitrile rubber’s strength, elasticity, and abrasion and tear resistance. These advancements are leading to the growth of high-performance nitrile rubber for applications including aerospace, Oil Gas, and extreme industrial applications.

Furthermore, improvements in the ways of producing nitrile rubber imply cost reduction that will open new sectors to its use. Today, we are witnessing that these technologies help manufacturers to develop and produce solutions targeted at specific industrial applications.

Increase in the Sales of Nitrile Gloves after COVID-19 Pandemic

The current global pandemic has brought into focus the usage of these personal protective equipment (PPEs) and among them nitrile gloves. The demand for the product continues to be felt most in the healthcare sector, although other sectors like food processing and pharmaceuticals, hotels, and restaurants are adopting the use of gloves as measures of hygiene. After this pandemic, there will be consistent demand for nitrile gloves because industries will continue to protect their workers from infections.

Access sample report (including graphs, charts, and figures): https://univdatos.com/get-a-free-sample-form-php/?product_id=23257

Fluctuations in the Costs of Raw Material

Nitrile rubber is synthesized from acrylonitrile rubber/butadiene which are petrochemical-based materials whose cost will change with the world oil prices as well as market trends. Fluctuations in raw material prices are influential on nitrile rubber manufacturers and can force price changes in utilization markets. In this respect, certain firms are looking for other sources of the mineral or increasing the production intensity.

Environmental Issues on Synthetic Polymers

Critics target nitrile rubber because it is a synthetic polymer and its disposal is a problem because the material is nonbiodegradable. Weaknesses of nitrile rubber include difficulties regarding environment compliance and waste management as more and more stringent environmental laws are developed and the call for environmentally friendly materials is raised. Nevertheless, trends in green chemistry, new environmentally friendly technologies, and gradually strengthening the recyclability requirements should reduce these problems.

Conclusion

Subsequently, there are high projections for the global market of nitrile rubber as the product found application in the automotive, Industrial, Healthcare, and Construction industries among others. The necessity of the material can be understood through the acknowledgment of its application in industries that need high-performance elastomers. However, the industry is not without challenges, that range from fluctuating raw material prices to environmental issues that are gradually forcing the manufacturers to become innovative in the use of environmentally friendly products.

From the forecast point of view, the development of the sustainability index, and the further scientific breakthrough of polymers provide the chances of a change in the nitrile rubber market. Since industries continue to emphasize safety, productivity, and sustainability, nitrile rubber will continue to be an essential material in supply chain networks. Car and healthcare industries, and industrial manufacturing to name but a few will continue to drive the demand for nitrile rubber in the next few years, keeping this valuable material afloat in the rubber market.

Contact Us:

UnivDatos Market Insights

Contact Number - +1 9782263411

Email - contact@univdatos.com

Website - www.univdatos.com

Linkedin- https://www.linkedin.com/company/univ-datos-market-insight/mycompany/

Related Chemical Market Research Industy Report:-

Phase Change Material Market: Current Analysis and Forecast (2024-2032)

Maleic Anhydride Market: Current Analysis and Forecast (2024-2032)