Introduction to HIL Testing

In the modern era of technological advancements, testing plays a crucial role in product development. One such innovative method is Hardware-in-the-Loop (HIL) Testing. It is a process where real-time simulation meets hardware to validate the performance of complex systems. But why is HIL Testing becoming so popular? Let’s dive in to find out!

What Is HIL Testing?

HIL Testing, or Hardware-in-the-Loop Testing, is a technique used to validate the performance of embedded systems by simulating real-world scenarios. Think of it as a dress rehearsal before the actual performance, where you test every component in a controlled environment to ensure everything works perfectly in the real world.

Why HIL Testing Is Important

Ever wondered why products fail even after extensive testing? Traditional testing methods may not capture all real-world scenarios. HIL Testing bridges this gap by mimicking real-world conditions, allowing for comprehensive validation. This not only reduces the risk of failures but also accelerates the development process.

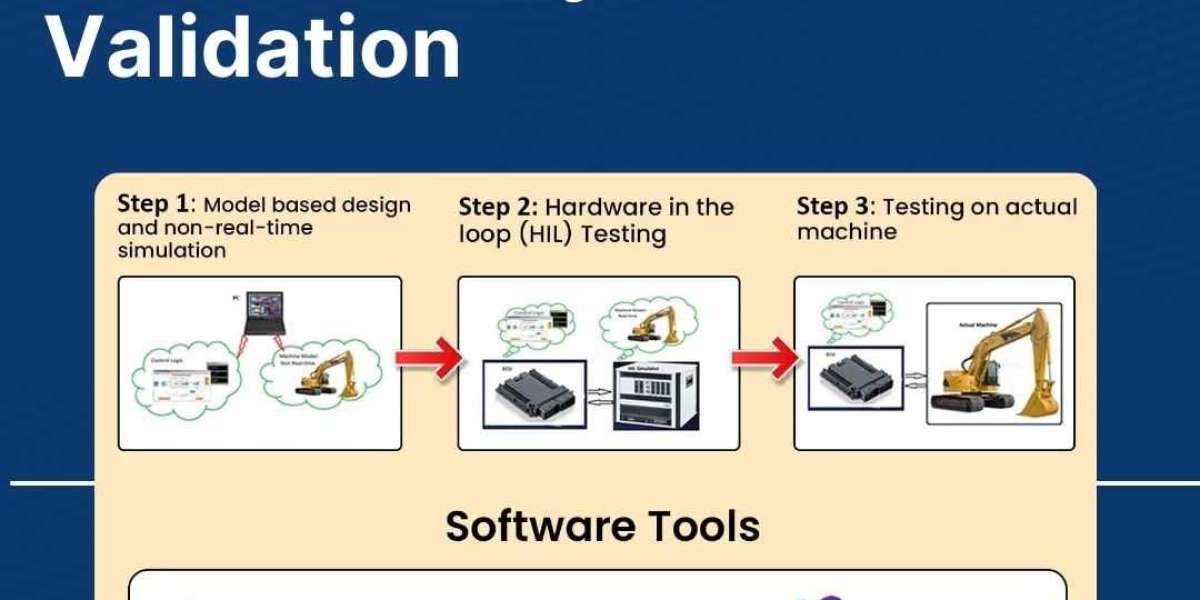

How HIL Testing Works

HIL Testing integrates a simulation model with real hardware components. The simulated environment mimics real-world inputs like speed, temperature, and load, which interact with the actual system. This process helps identify issues early on, preventing costly fixes down the line.

Key Components of HIL Testing

To understand HIL Testing better, let's look at its core components:

- Real-Time Simulator: The heart of HIL Testing, providing real-time inputs and feedback.

- Actuators and Sensors: These are the real hardware parts tested in the simulation.

- Controller: Manages the response of the system to different simulated conditions.

- User Interface: Allows engineers to control and monitor the testing process.

Benefits of HIL Testing

The advantages of HIL Testing are numerous:

- Cost-Effective: It reduces the need for physical prototypes, saving time and money.

- Risk Reduction: By simulating real-world conditions, it identifies issues before full-scale production.

- Faster Development: Speeds up the testing process, allowing quicker time to market.

HIL Testing in Automotive Industry

In the automotive sector, HIL Testing has become a game-changer. It helps in testing Advanced Driver Assistance Systems (ADAS), electric vehicle controllers, and various safety features. Imagine being able to test a car’s braking system without putting it on the road—HIL Testing makes it possible!

Common Challenges in HIL Testing

While HIL Testing offers many benefits, it comes with its own set of challenges:

- Complex Setup: Requires a detailed understanding of both hardware and simulation software.

- High Initial Cost: The investment in setting up HIL Testing can be substantial but pays off in the long run.

- Integration Issues: Ensuring that all components work seamlessly together can be tricky.

Best Practices for HIL Testing

To make the most of HIL Testing, follow these best practices:

- Plan Thoroughly: Define test cases and objectives clearly.

- Use High-Quality Models: Accurate simulation models are essential for reliable results.

- Regular Calibration: Keep hardware and software calibrated to maintain test accuracy.

- Iterative Testing: Repeatedly test and refine to catch errors early.

Future Trends in HIL Testing

The future of HIL Testing looks promising, with advancements in AI, machine learning, and cloud-based simulations. These technologies are expected to enhance the accuracy and speed of HIL Testing, making it even more integral to product development processes.

Conclusion

HIL Testing is revolutionizing how we approach product validation and software testing. By providing a realistic testing environment, it ensures systems are robust, reliable, and ready for real-world applications. Companies like Servotech are at the forefront of offering expert HIL Testing services, ensuring your products meet the highest standards of quality and performance.

Frequently Asked Questions (FAQs)

- What is HIL Testing used for?

- HIL Testing is primarily used for validating embedded systems by simulating real-world conditions, especially in the automotive and aerospace industries.

- How does HIL Testing differ from traditional testing?

- Unlike traditional testing, HIL Testing integrates real hardware with a simulated environment, allowing for more accurate and comprehensive testing.

- Is HIL Testing expensive to implement?

- While the initial setup can be costly, HIL Testing saves money by reducing the need for physical prototypes and minimizing the risk of product failures.

- Can HIL Testing be used for software-only systems?

- HIL Testing can be adapted for software validation by simulating hardware inputs and analyzing software responses.

- What industries benefit the most from HIL Testing?

- Industries like automotive, aerospace, and electronics manufacturing benefit greatly from HIL Testing due to their products' complexity and safety requirements.