Custom steel pipe fabrication is a critical process in various industries, providing tailored solutions for specific applications. Understanding the intricacies of this process can significantly enhance your project outcomes. In this guide, we will delve into the essential aspects of custom steel pipe fabrication, including the processes involved, materials used, and their diverse applications.

Understanding Custom Steel Pipe Fabrication

What exactly is custom steel pipe fabrication? This process involves the design and manufacturing of steel pipes to meet specific requirements. Unlike standard pipes, custom options allow for unique dimensions, shapes, and finishes, catering to the precise needs of a project. This flexibility is crucial in industries such as construction, oil and gas, and manufacturing.

Key Processes in Custom Steel Pipe Fabrication

The fabrication of custom steel pipes typically involves several key processes:

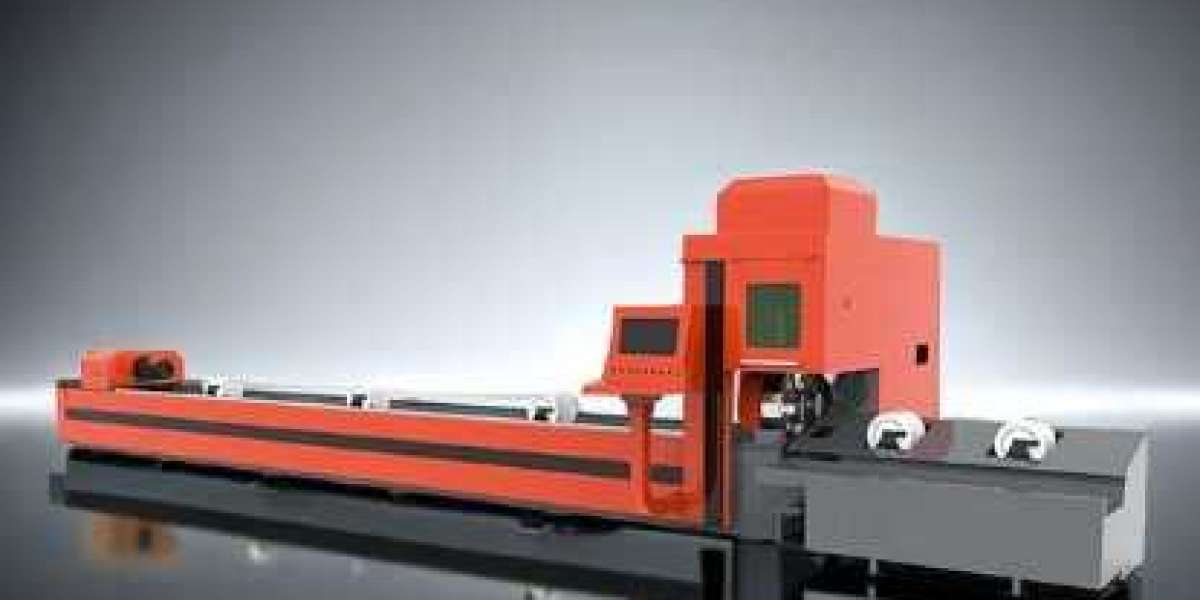

- Cutting: Steel pipes are cut to the required lengths using various methods, including saw cutting and plasma cutting.

- Bending: Pipes can be bent to fit specific angles and curves, ensuring they meet the design specifications.

- Welding: This process joins sections of pipe together, providing strength and durability.

- Finishing: Custom steel pipes may undergo finishing processes, such as coating or polishing, to enhance their appearance and resistance to corrosion.

Materials Used in Custom Steel Pipe Fabrication

When it comes to custom steel pipe fabrication, the choice of materials is paramount. Common materials include:

- Carbon Steel: Known for its strength and durability, carbon steel is widely used in various applications.

- Stainless Steel: This material offers excellent corrosion resistance, making it ideal for environments exposed to moisture.

- Alloy Steel: Alloy steels are tailored for specific properties, such as increased strength or improved wear resistance.

Applications of Custom Steel Pipe Fabrication

Custom steel pipes find applications across numerous sectors. Some notable uses include:

- Construction: Custom pipes are essential for structural support and plumbing systems.

- Oil and Gas: These pipes are crucial for transporting oil and gas safely and efficiently.

- Manufacturing: Custom steel pipes are used in machinery and equipment, enhancing operational efficiency.

Conclusion

In conclusion, understanding custom steel pipe fabrication is vital for professionals in various industries. By grasping the processes, materials, and applications involved, you can make informed decisions that enhance your projects. For more information on custom steel pipe fabrication and to explore high-quality options, visit  .

.