Lasers have revolutionized numerous industries, from medical treatments to manufacturing and scientific research. Among the various types of lasers, pulse lasers stand out for their unique characteristics and applications. Pulse lasers are designed to emit light in short bursts or pulses, rather than a continuous stream of light. This ability to deliver high-intensity energy in brief bursts has made pulse lasers critical in modern technological applications.

In this article, we’ll explore what makes pulse lasers unique, why they’re critical in various fields, and how to use them effectively for optimal results.

What is a Pulse Laser?

A pulse laser is a type of laser that emits light in the form of discrete, high-energy pulses, instead of a continuous beam. These pulses can be incredibly short, ranging from femtoseconds (quadrillionths of a second) to nanoseconds (billionths of a second). Pulse lasers are characterized by their ability to deliver very high power in each pulse, making them suitable for applications where high-intensity energy is needed over a short duration.

How Pulse Lasers Work

Pulse lasers operate based on the principle of light amplification by stimulated emission of radiation (LASER). In a pulse laser, a material or medium (such as a gas, solid, or liquid) is excited, either electrically or optically, to a higher energy state. The laser system then releases energy in the form of light pulses as the material returns to a lower energy state.

The length of the pulses and the power contained in each pulse depend on the design and the purpose of the laser. A pulse laser may emit anywhere from a few pulses per second to several million pulses per second, depending on its application.

What Makes Pulse Lasers Unique?

Pulse lasers have several unique features that distinguish them from other types of lasers, such as continuous-wave (CW) lasers. These include:

1. High Peak Power

The most significant feature of pulse lasers is their ability to deliver high peak power. In a single pulse, a pulse laser can generate an enormous amount of energy in a very short time. This capability makes pulse lasers ideal for applications requiring intense energy bursts, such as cutting, welding, or material processing.

2. Short Pulse Duration

Pulse lasers are defined by their pulse duration, which is the amount of time it takes for each pulse to complete. The shorter the pulse, the higher the peak power it delivers. Pulse lasers can be designed to emit pulses that last anywhere from a few femtoseconds to nanoseconds, with ultrafast lasers capable of producing pulses as short as femtoseconds. These extremely short pulses are useful for high-precision applications.

3. Energy Concentration

Because pulse lasers release energy in concentrated bursts, they can focus high levels of energy on a tiny area. This concentration of energy makes them ideal for micro-machining, laser surgery, and precision cutting tasks, where a fine focus is needed without affecting the surrounding material.

4. Wide Range of Wavelengths

Pulse lasers can be designed to emit light across a broad spectrum of wavelengths, including visible, infrared, and ultraviolet light. This allows pulse lasers to be adapted for use in a wide range of applications, from medical procedures to industrial processes.

5. Reduced Thermal Damage

Due to the short duration of each pulse, pulse lasers are less likely to cause thermal damage to the surrounding material compared to CW lasers. This makes pulse lasers highly effective in applications where heat buildup could cause damage, such as in delicate tissue during surgery or fine materials in manufacturing.

Why Pulse Lasers are Critical in Modern Applications

Pulse lasers have found their place in a wide range of modern industries, and their unique characteristics make them essential for various applications. Below are some of the critical areas where pulse lasers are used:

1. Medical Field

In medicine, pulse lasers are used for precise surgeries, including eye surgeries (such as LASIK), laser hair removal, and dental procedures. The ability of pulse lasers to focus energy on specific tissues without damaging surrounding areas is invaluable in these delicate procedures. Pulse lasers are also used in skin resurfacing, tumor treatment, and vaporization of kidney stones.

2. Manufacturing and Material Processing

Pulse lasers are crucial in material processing applications, such as cutting, welding, drilling, and engraving. Their ability to concentrate high energy on a small area allows them to work with a wide variety of materials, including metals, plastics, and ceramics. Laser marking and micro-machining are common uses of pulse lasers in manufacturing.

3. Scientific Research

Pulse lasers are widely used in scientific research, particularly in spectroscopy, microscopy, and time-resolved experiments. The ability to generate ultrafast pulses makes them indispensable tools for investigating chemical reactions, material properties, and biological processes at a microscopic level.

4. Military and Defense

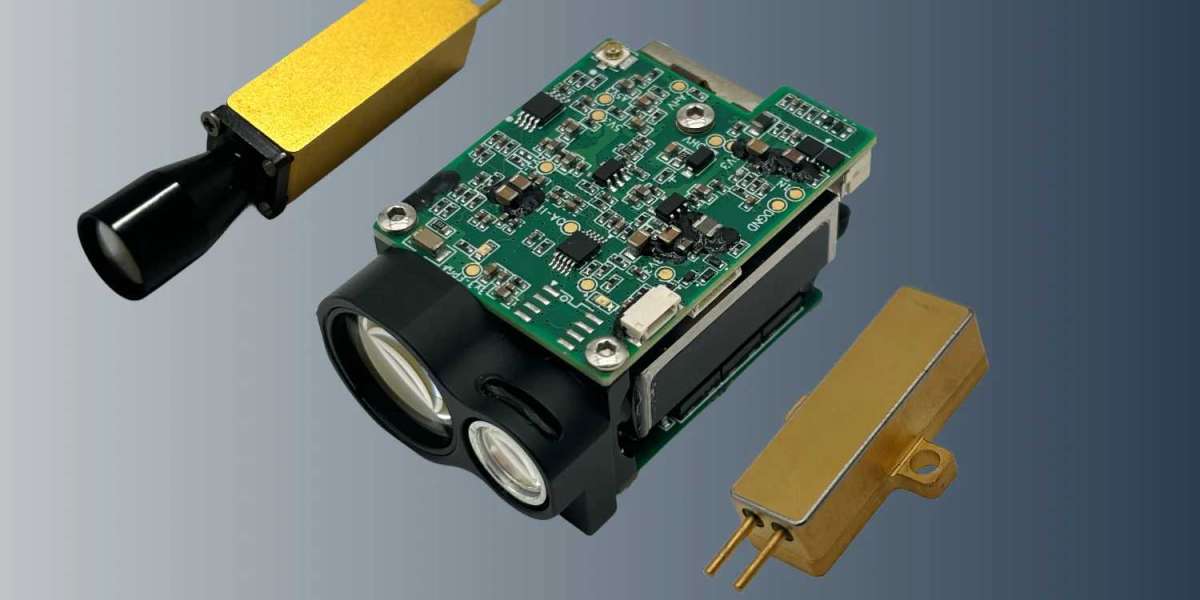

Pulse lasers play a role in defense systems, where they are used for targeting and detection in various military systems. For example, laser range finders and targeting systems rely on pulse lasers to measure distances or accurately pinpoint targets. In laser weapons research, pulse lasers are also considered for their potential to disable or destroy targets.

5. Communication Systems

Pulse lasers are used in fiber optic communication systems to transmit data at high speeds over long distances. In these systems, pulses of light are transmitted through optical fibers, allowing for faster data transfer compared to traditional copper wires.

6. Environmental Monitoring

Pulse lasers are used in LiDAR (Light Detection and Ranging) systems for topographical mapping, environmental monitoring, and forestry applications. By emitting pulses and measuring the time it takes for the pulses to return, pulse lasers can create high-resolution 3D maps of terrains, monitor vegetation growth, and even assess atmospheric conditions.

How to Use Pulse Lasers Effectively

While pulse lasers are versatile and powerful, using them effectively requires understanding the specific requirements of your application. Below are some tips for using pulse lasers efficiently:

1. Understand Pulse Duration and Energy

The success of a pulse laser application often depends on the balance between pulse duration and energy output. For example, in cutting or welding, a laser with a short pulse duration and high energy is ideal for creating precise cuts in materials. However, for medical procedures like eye surgery, a longer pulse duration may be preferred to reduce the likelihood of damaging healthy tissue.

2. Adjust Power Settings Based on Material

Different materials respond to laser energy differently. In material processing, it’s essential to adjust the pulse energy and frequency to match the properties of the material being worked on. For instance, metals may require higher energy pulses, while plastics or delicate materials may need lower-energy, shorter pulses to avoid deformation.

3. Use Focusing Optics for Precision

Pulse lasers can achieve high precision whenmbined with the right focusing optics. By focusing the laser to a very small spot size, users can achieve highly accurate results in tasks such as micro-machining or engraving. Proper focus is key to maximizing the effectiveness of the laser.

4. Consider Cooling and Thermal Management

Pulse lasers can generate significant heat during operation, especially if used for high-energy applications. In such cases, it’s crucial to have effective cooling systems in place to prevent overheating, which could reduce the laser’s performance and lifespan.

5. Monitor Pulse Frequency

The frequency at which pulses are emitted, often measured in Hertz (Hz), affects the overall performance of the pulse laser. Higher pulse frequencies are beneficial for faster operations, such as in scanning or imaging, while lower frequencies are often used in applications requiring more energy per pulse.

Conclusion

Pulse lasers are unique, powerful tools with a wide range of applications across various industries, including medicine, manufacturing, research, defense, and environmental monitoring. Their ability to deliver high-intensity energy in short bursts, along with their precision, makes them essential in modern technological advancements. By understanding the specific requirements of your application, adjusting settings accordingly, and using the right accessories, you can maximize the effectiveness of pulse lasers and harness their full potential in your work.

More Info: https://erdicn.com/