In recent years, the construction industry has witnessed significant advancements in technology, leading to more efficient and sustainable building practices. One such innovation is the experimental vacuum brick extruder, a cutting-edge machine that revolutionizes the process of brick manufacturing. In this article, we will explore the advantages and features of this groundbreaking technology.

I. Understanding the Experimental Vacuum Brick Extruder

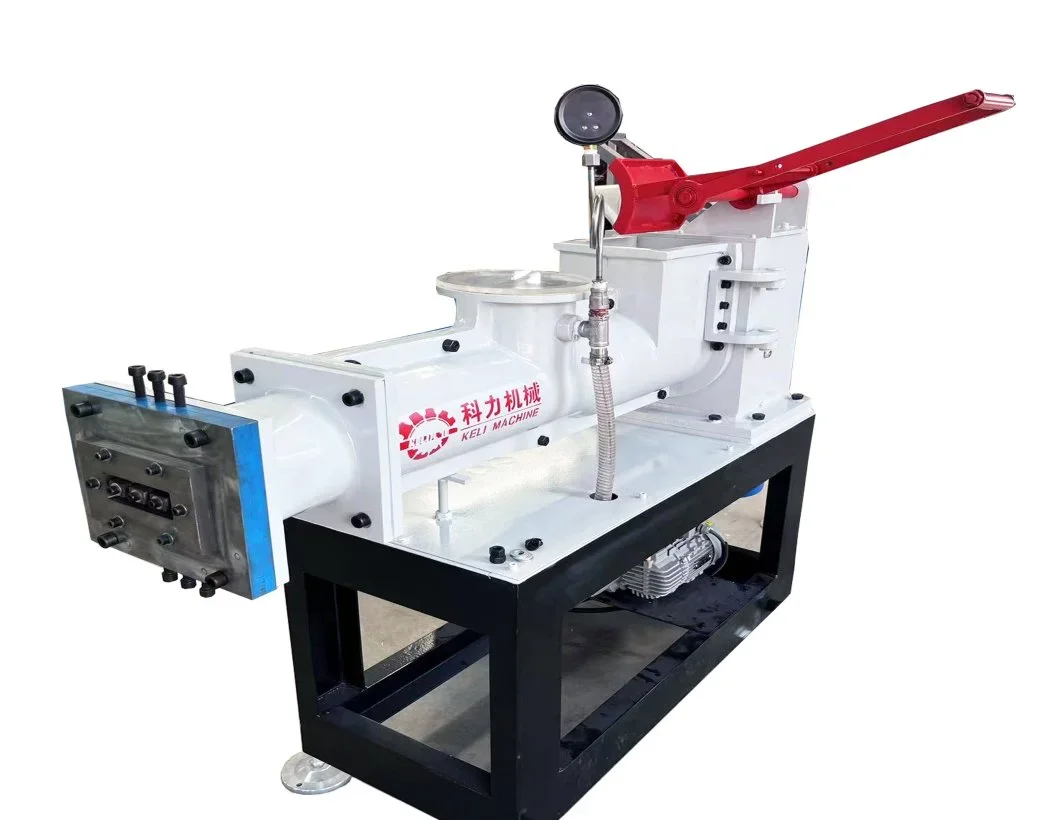

The https://www.yxkelijixie.com/Experimental-vacuum-extruder.html is a specialized machine designed to produce high-quality bricks using a vacuum-assisted extrusion process. It combines the principles of vacuum technology and brick making to create a more efficient and precise manufacturing process.

II. Advantages of Experimental Vacuum Brick Extruder

1. Enhanced Efficiency

The experimental vacuum brick extruder offers significant advantages in terms of efficiency. By utilizing vacuum technology, it ensures a more consistent and uniform brick production process. The vacuum assists in removing excess air and moisture from the clay mixture, resulting in better compaction and improved brick quality.

2. Higher Productivity

Compared to traditional brick manufacturing methods, the experimental vacuum brick extruder allows for higher productivity. The machine can produce a larger number of bricks in a shorter period, reducing production time and costs. This increased productivity is especially beneficial for large-scale construction projects.

3. Improved Brick Quality

One of the key advantages of the experimental vacuum brick extruder is the superior quality of the bricks it produces. The vacuum-assisted extrusion process ensures better compaction, resulting in bricks with higher density and strength. These high-quality bricks offer enhanced durability and resistance to weathering, making them ideal for various construction applications.

4. Cost Savings

The experimental vacuum brick extruder offers cost savings in multiple ways. Firstly, the higher productivity and efficiency of the machine reduce labor costs and overall production expenses. Additionally, the improved quality of the bricks reduces the need for repairs and replacements, resulting in long-term cost savings for builders and homeowners.

III. Features of Experimental Vacuum Brick Extruder

1. Vacuum Chamber

The experimental vacuum brick extruder features a vacuum chamber where the clay mixture is processed. The vacuum chamber creates a controlled environment for extrusion, ensuring optimal compaction and removal of air and moisture from the clay.

2. Extrusion System

The extrusion system of the machine consists of a screw or piston mechanism that pushes the clay mixture through a die to form the desired brick shape. The experimental vacuum brick extruder offers precise control over the extrusion process, allowing for consistent brick dimensions and shapes.

3. Clay Preparation Unit

To ensure the proper consistency and quality of the clay mixture, the experimental vacuum brick extruder is equipped with a clay preparation unit. This unit includes a mixer and a feeder that blend the clay with water and other additives, creating a homogenous mixture suitable for extrusion.

4. Control Panel

The control panel of the experimental vacuum brick extruder allows operators to monitor and adjust various parameters of the machine. This includes controlling the vacuum level, extrusion speed, and temperature, ensuring optimal conditions for brick production.

IV. Applications of Experimental Vacuum Brick Extruder

The experimental vacuum brick extruder has a wide range of applications in the construction industry. Some of the key areas where this technology is being utilized include:

1. Residential Construction: The high-quality bricks produced by the experimental vacuum brick extruder are ideal for residential buildings, offering durability and aesthetic appeal.

2. Commercial Construction: The efficiency and productivity of the machine make it suitable for large-scale commercial construction projects, where a significant number of bricks are required.

3. Sustainable Building Practices: The experimental vacuum brick extruder aligns with sustainable building practices by reducing waste, energy consumption, and environmental impact.

Conclusion

The experimental vacuum brick extruder represents a significant advancement in brick manufacturing technology. With its enhanced efficiency, higher productivity, improved brick quality, and cost savings, this innovative machine is transforming the construction industry. As the demand for sustainable and high-quality building materials continues to grow, the experimental vacuum brick extruder is poised to play a crucial role in shaping the future of construction.

KeLi Machine is a leading manufacturer and supplier of advanced machinery and equipment for the construction industry. With a focus on innovation and quality, we provide cutting-edge solutions that improve productivity, efficiency, and sustainability.

Visit our website to learn more about our products.

Welcome to inquiry if you need to know more about experimental vacuum brick extruder details or order wholesale.

Website:www.yxkelijixie.com

Email:[email protected]