In today's fast-paced world, industries and professionals are constantly searching for faster, more efficient ways to maintain their equipment and preserve their valuable assets. One such breakthrough solution is the rust cleaning laser – a game-changer in the world of rust removal. The LaserCleaner technology utilizes high-powered laser beams to safely and effectively clean rust, corrosion, and contaminants from various surfaces. Whether you're in the manufacturing, automotive, or maritime industry, the LaserCleaner offers a modern, eco-friendly solution to keep your machinery and structures in pristine condition.

Why Rust Cleaning Laser Technology is the Future

Rust is not just a cosmetic issue; it's a sign of deterioration that can compromise the structural integrity of metal objects, leading to expensive repairs, replacements, and downtime. Traditional rust cleaning methods, like sandblasting or chemical treatments, can be time-consuming, labor-intensive, and harmful to the environment. That's where the rust cleaning laser technology comes in.

LaserCleaner uses a high-intensity laser beam to interact with the rust or corrosion on a metal surface. The laser’s energy is absorbed by the rust, which causes it to vaporize or break off from the surface, leaving the underlying material untouched. This precise, contact-free method ensures minimal wear and tear, even on delicate or intricate surfaces. The rust cleaning laser can be used on a wide variety of metals, including steel, aluminum, and iron, making it suitable for a range of industries.

Key Benefits of Laser Rust Removal

Eco-Friendly: Unlike traditional rust removal techniques, laser cleaning eliminates the need for harsh chemicals or abrasive materials. There's no need for chemical waste disposal, reducing the environmental impact.

Precision and Efficiency: The laser beam targets only the rust and corrosion, leaving the underlying material untouched. It’s an extremely precise cleaning method that reduces the risk of damaging the surface.

Cost-Effective: While initial investment costs may be higher than traditional methods, laser cleaning is more cost-effective in the long run. It reduces the need for consumables like abrasive media, chemicals, and water, which cuts operational costs.

Non-Contact Process: The laser cleaning process doesn’t involve any direct contact with the surface, eliminating the risk of scratches or dents. This is especially beneficial for cleaning delicate or high-value parts.

Minimal Maintenance: LaserCleaner systems require little maintenance and have a long lifespan. With fewer moving parts and no abrasive media, they offer exceptional durability.

Speed and Versatility: Rust cleaning lasers are fast, capable of cleaning large areas in a fraction of the time it would take using traditional methods. Plus, they can be used on a variety of surfaces, shapes, and sizes, making them incredibly versatile for different applications.

Applications of Laser Rust Removal

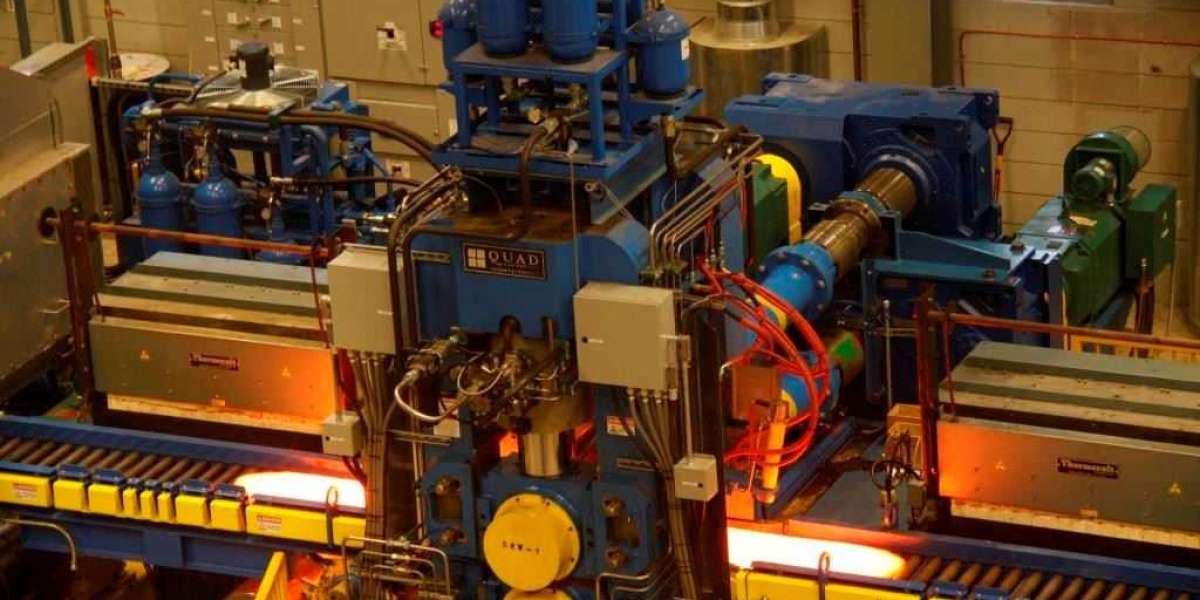

Industrial Equipment: Manufacturing plants and factories use laser cleaning to maintain equipment, reducing the risk of corrosion and extending the life of machinery.

Automotive Industry: Laser cleaners help remove rust from car parts and components, ensuring a high-quality finish and preventing further corrosion.

Marine and Shipbuilding: The maritime industry, plagued by constant exposure to saltwater, benefits greatly from the rust cleaning laser to prevent costly repairs and ensure the longevity of ships.

Historic Restoration: Laser rust cleaning is used to restore and preserve historical metal objects, statues, and monuments, keeping their integrity intact without causing further damage.

Construction: Construction machinery and infrastructure maintenance can be improved with laser cleaning, ensuring that rust doesn't compromise the safety or function of critical assets.

The Future of Rust Removal

The potential applications of rust cleaning laser technology are virtually endless. As industries continue to seek more sustainable and efficient solutions, laser cleaning stands out as a top contender in the race for innovation. Not only does it offer a solution to rust and corrosion, but it also paves the way for more precise and eco-conscious cleaning methods in various sectors.

As the LaserCleaner technology evolves, we can expect even faster, more powerful lasers, improved portability, and more adaptable systems. Whether you're looking to restore a small metal object or clean large industrial machinery, the future of rust removal is clear: LaserCleaner is here to stay.