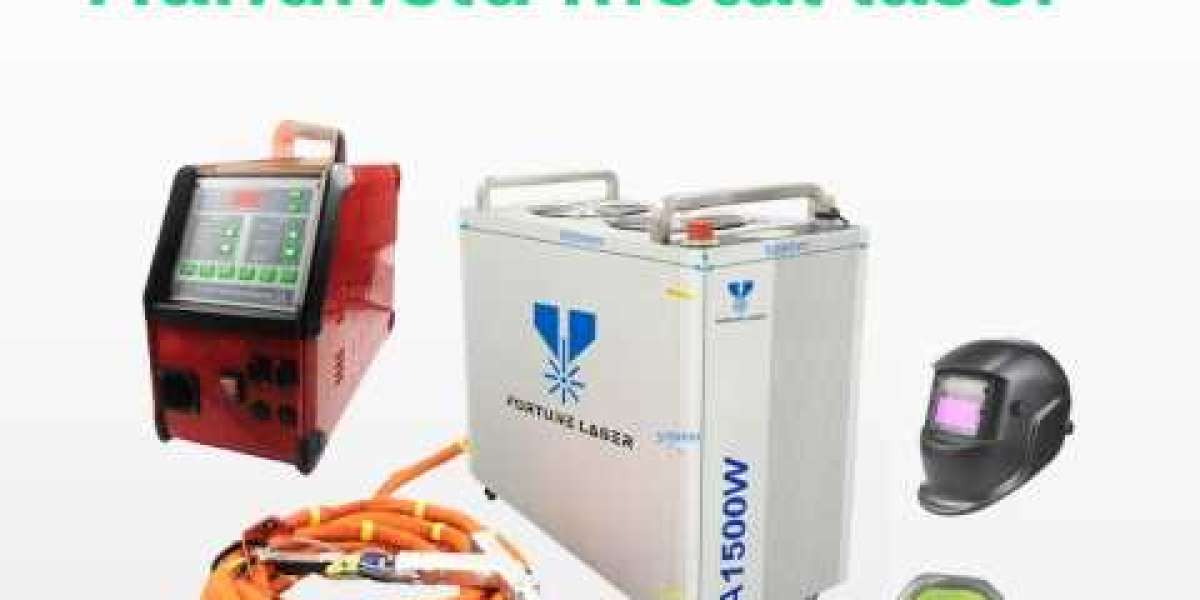

In the world of metalworking, precision and efficiency are crucial. Traditional methods of cutting and welding metal often involve bulky machinery, complex setups, and significant time investments. However, the introduction of handheld metal laser has revolutionized the industry. These portable devices offer unmatched flexibility, allowing users to cut, weld, and engrave metal with pinpoint accuracy. Whether you're in manufacturing, automotive, or jewelry design, a handheld metal laser can significantly improve productivity and results.

What is a Handheld Metal Laser?

A handheld metal laser is a portable device that uses laser technology to cut, weld, or engrave various metals. It utilizes a high-powered laser beam to achieve precise modifications, making it ideal for applications that require accuracy and efficiency. These devices are commonly used in industries such as aerospace, electronics, shipbuilding, and custom fabrication.

Key Features of a Handheld Metal Laser

- Portability Ease of Use – Unlike traditional laser machines, handheld metal lasers are compact and lightweight, making them easy to maneuver.

- High Precision Accuracy – The focused laser beam ensures clean and precise cuts, reducing material waste.

- Fast Operation – Handheld metal lasers operate at high speeds, increasing work efficiency.

- Versatile Applications – Suitable for cutting, welding, engraving, and marking different metals, including stainless steel, aluminum, copper, and titanium.

- Minimal Heat Damage – The advanced laser technology prevents excessive heat from spreading, reducing distortion or burns on the metal surface.

Applications of Handheld Metal Lasers

- Metal Cutting – Ideal for precision cutting in industries like construction, manufacturing, and engineering.

- Metal Welding – A great alternative to traditional welding methods, providing clean and strong welds without excessive heat.

- Metal Engraving – Used for creating intricate designs and branding on jewelry, tools, and industrial parts.

- Automotive Repairs – Efficient for welding car body parts and repairing metal components.

- Aerospace Shipbuilding – Used for high-precision cutting and welding in large-scale industrial projects.

Benefits of Using a Handheld Metal Laser

- Cost-Effective – Reduces the need for multiple tools and labor-intensive processes.

- Environmentally Friendly – Produces minimal waste and does not require harmful chemicals.

- Enhanced Productivity – Accelerates production times with high-speed operation.

- User-Friendly – Requires minimal training and allows for greater flexibility in complex projects.

Conclusion

A handheld metal laser is an innovative tool that enhances efficiency, precision, and versatility in metalworking. Whether you need to cut, weld, or engrave metal, this device provides an effective solution across various industries. Investing in a handheld metal laser can improve workflow, reduce operational costs, and elevate the quality of your work. If you're looking to upgrade your metalworking capabilities, a handheld metal laser is undoubtedly a worthwhile investment.