The use of Valve Bags can result in significant economic benefits for businesses involved in bulk packaging. These bags are designed to streamline the packaging process, reduce material costs, and improve operational efficiency, all of which contribute to long-term savings.

One of the main reasons valve bags are considered cost-effective is their simple design. The built-in valve eliminates the need for additional sealing equipment, making it a more affordable option compared to traditional methods. Additionally, valve bags are typically made from lightweight materials, which reduces the overall weight of the packaging, lowering shipping costs.

The efficiency of valve bags also leads to reduced labor costs. Automated filling systems can be used with these bags, minimizing the need for manual labor during the packaging process. This automation not only saves on labor expenses but also increases the speed at which products are packaged, leading to higher output levels.

Another economic advantage of valve bags is their ability to minimize material waste. The precise filling process reduces the chances of overfilling or underfilling, ensuring that each bag is optimally packed. This accuracy helps businesses avoid excess material use and reduce packaging costs.

In summary, valve bags offer businesses a practical solution that reduces both operational and material costs, making them a valuable investment in the packaging industry.

https://www.packingbagfactory.com/product/paper-plastic-composite-bags/white-paper-plastic-composite-middle-seam-bag.html

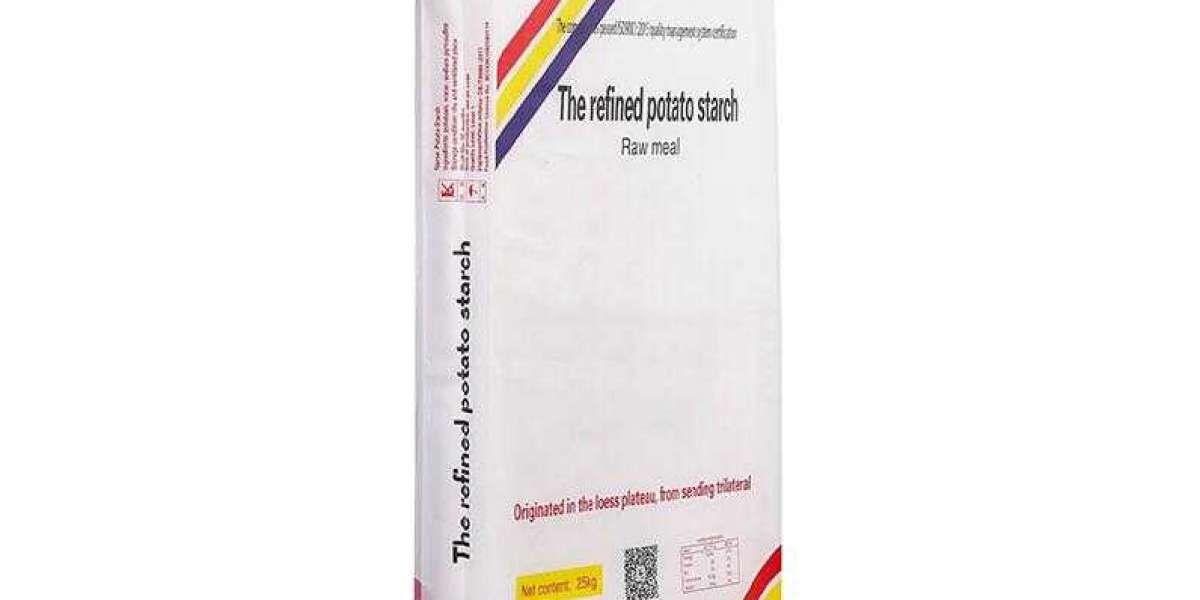

The White Paper Plastic Composite Middle Seam Bag is an innovative packaging solution that combines the strength and durability of paper with the flexibility and moisture resistance of plastic. This unique composite structure is designed to provide an ideal solution for various industries, including food, chemicals, construction, and agricultural sectors.