gas detection system malaysia, industrial facilities that handle hazardous gases must prioritize workplace safety to prevent accidents, comply with safety regulations, and maintain operational efficiency. Gas detection systems play a critical role in ensuring that toxic and flammable gases are identified before they reach dangerous levels. With technological advancements, modern gas detection solutions now offer enhanced accuracy, real-time monitoring, and seamless integration with existing safety infrastructures.

As industries such as oil and gas, chemical processing, and manufacturing continue to expand in Malaysia, the adoption of reliable gas detection solutions is more important than ever.

Understanding the Need for Gas Detection Systems

Industrial environments can expose workers to various hazardous gases, including:

- Toxic Gases – Carbon monoxide (CO), hydrogen sulfide (H₂S), chlorine (Cl₂), and ammonia (NH₃).

- Flammable Gases – Methane (CH₄), propane (C₃H₈), and hydrogen (H₂).

- Oxygen Deficiency – In confined spaces, oxygen levels can drop dangerously low, posing a risk to workers.

A gas detection system helps to:

✔ Continuously monitor gas levels to prevent overexposure.

✔ Trigger alarms when hazardous gas concentrations are detected.

✔ Automatically activate ventilation systems to mitigate risks.

✔ Provide data for compliance reporting and safety improvements.

Innovations in Gas Detection Technology

With the rapid evolution of industrial safety solutions, gas detection technology has also advanced significantly. Some of the latest innovations in gas detection systems include:

1. Smart Gas Detectors with IoT Integration

- Provides real-time data monitoring and alerts through mobile applications.

- Allows safety teams to monitor gas levels remotely.

- Reduces response times during gas leak incidents.

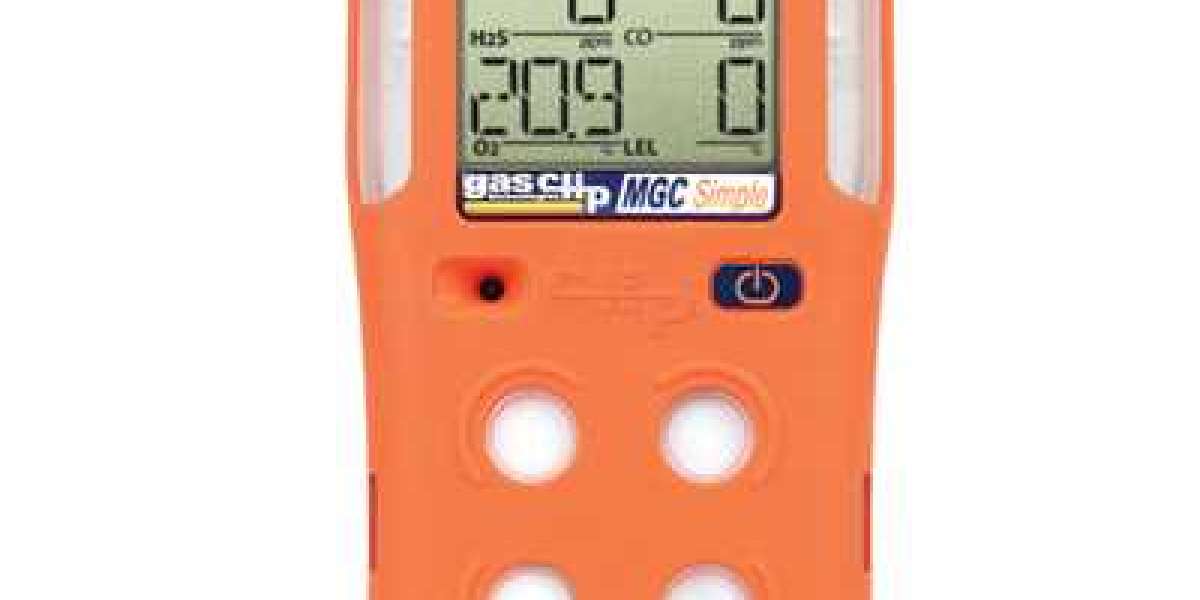

2. Multi-Gas Detection Systems

- Can simultaneously detect multiple hazardous gases.

- Ideal for industries dealing with a variety of gases, such as chemical plants and oil refineries.

3. AI-Based Predictive Gas Monitoring

- Uses artificial intelligence to predict gas leak patterns and prevent potential accidents.

- Enhances workplace safety by identifying high-risk areas before leaks occur.

Implementation of Gas Detection Systems in Malaysian Industries

Industries in Malaysia are increasingly adopting advanced gas detection solutions to improve workplace safety. Some key industries that benefit from gas detection systems include:

- Oil and Gas – Continuous monitoring of flammable gases and toxic vapors.

- Chemical Processing – Detection of hazardous chemical leaks.

- Manufacturing – Monitoring of gas emissions in production facilities.

- Waste Treatment Plants – Detection of harmful gases such as methane and hydrogen sulfide.

Regulatory Compliance and Industry Standards

To ensure safety, Malaysian industries must adhere to strict gas detection regulations, including:

✔ Occupational Safety and Health Act (OSHA) 1994 – Requires industries to provide a safe working environment.

✔ ISO 45001 Occupational Health and Safety Standard – Provides guidelines for workplace hazard prevention.

✔ DOSH Guidelines for Confined Spaces – Mandates gas monitoring in confined areas such as storage tanks and tunnels.

Compliance with these standards not only enhances workplace safety but also prevents legal and financial consequences for companies.

Conclusion

Gas detection systems are a critical component of industrial safety in Malaysia. By investing in modern, technologically advanced gas detection solutions, businesses can protect their workforce, prevent costly accidents, and ensure compliance with safety regulations. As industries continue to evolve, embracing smart and AI-driven gas detection systems will play a crucial role in maintaining workplace safety and operational efficiency.