In the dynamic realm of textile manufacturing, the increasing demand for precision, efficiency, and adaptability has spurred remarkable advancements in sewing technology. Among these innovations, the cylinder bed computer-controlled sewing machine has emerged as a transformative tool. These machines have fundamentally changed textile production by providing exceptional capabilities for a wide range of applications. This article will delve into the versatility of cylinder bed computer-controlled sewing machines and their significant impact on the textile industry.

What is a Cylinder Bed Computer Controlled Sewing Machine?

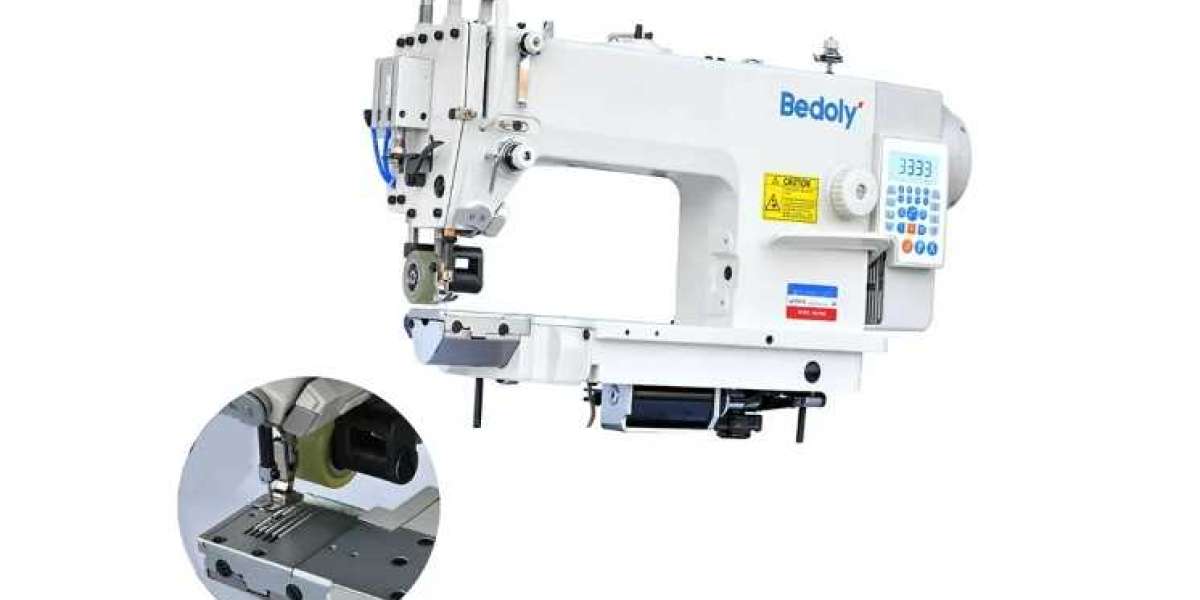

A cylinder bed computer-controlled sewing machine is a specialized type of sewing machine that features a cylindrical bed instead of a flat one. This design allows for greater flexibility and ease when working with tubular or curved materials, such as sleeves, cuffs, and collars. The computer-controlled aspect enables precise stitching and pattern customization, making these machines ideal for complex sewing tasks.

Advantages of Using Cylinder Bed Computer Controlled Sewing Machines

1. Enhanced Precision and Consistency

One of the primary benefits of cylinder bed computer-controlled sewing machines is their ability to produce highly precise stitches consistently. The computer control system allows for exact adjustments to stitch length, tension, and speed, ensuring that every seam is uniform. This precision is particularly important in high-quality garment production where even minor discrepancies can affect the overall appearance and functionality of the finished product.

2. Versatility in Applications

Cylinder bed machines are incredibly versatile and can be used for a wide range of applications within textile manufacturing:

Garment Production: Ideal for sewing intricate designs on clothing items such as shirts, dresses, and activewear.

Home Textiles: Suitable for producing items like curtains, cushions, and bedding where precision is key.

Automotive Upholstery: Effective in creating durable seams for car interiors that require both strength and aesthetic appeal.

Sports Equipment: Used in manufacturing goods like bags and protective gear where flexibility in fabric handling is essential.

3. Increased Efficiency

The high-speed capabilities of cylinder bed computer-controlled sewing machines contribute significantly to production efficiency. These machines can operate at speeds that surpass those of traditional sewing machines, allowing manufacturers to complete projects more quickly without sacrificing quality. Additionally, the ability to program multiple patterns reduces downtime associated with manual adjustments.

4. Reduced Labor Costs

With automation comes the potential for reduced labor costs. By investing in advanced cylinder bed machines, manufacturers can streamline their operations and minimize the need for extensive manual labor. This not only lowers labor costs but also allows skilled workers to focus on more complex tasks that require human intervention.

Applications in Textile Manufacturing

1. Apparel Industry

In the apparel sector, cylinder bed computer-controlled sewing machines are invaluable for producing garments with complex designs and shapes. They enable manufacturers to create intricate patterns while maintaining high production speeds. The ability to easily switch between different stitch patterns also allows for greater creativity in design.

2. Technical Textiles

The rise of technical textiles—fabrics engineered for specific performance characteristics—has increased the demand for specialized sewing solutions. Cylinder bed machines are well-suited for this application due to their ability to handle various fabric types and thicknesses while ensuring precise stitching that meets stringent performance standards.

3. Leather Goods Production

The leather industry benefits greatly from the versatility of cylinder bed machines as they can handle thicker materials that require specialized stitching techniques. These machines provide consistent results essential for products like bags, belts, and footwear.

4. Upholstery Work

In upholstery manufacturing, cylinder bed sewing machines facilitate the creation of custom furniture covers and automotive interiors by allowing easy maneuverability around curves and edges without compromising seam integrity.

Challenges in Implementing Cylinder Bed Machines

While cylinder bed computer-controlled sewing machines offer numerous advantages, there are challenges associated with their implementation:

1. Initial Investment Costs

The upfront costs associated with purchasing advanced machinery can be significant. However, many manufacturers find that the long-term savings from increased efficiency and reduced labor costs justify this initial investment.

2. Training Requirements

Operating sophisticated machinery requires skilled personnel who understand both the technical aspects of the machine and the intricacies of textile production. Investing in training programs is essential to maximize the benefits of these advanced systems.

3. Maintenance Needs

Like all machinery, cylinder bed sewing machines require regular maintenance to ensure optimal performance over time. Manufacturers must establish maintenance schedules and procedures to prevent downtime caused by equipment failure.

Conclusion

Cylinder bed computer-controlled sewing machines represent a significant advancement in textile manufacturing technology, offering unparalleled versatility, precision, and efficiency across various applications. As industries continue to evolve and adapt to changing consumer demands, these sophisticated machines will play an essential role in shaping the future of garment production and other textile-related fields.

Sanhexin Automation Co., Ltd., as a leader in developing innovative sewing solutions, contributes significantly to this transformation by providing high-quality cylinder bed machines tailored to meet diverse manufacturing needs. By embracing these advanced technologies, businesses can enhance their operational capabilities while ensuring product quality and meeting market demands effectively.

Advantages of Computer-Controlled Sewing Machines: Efficiency and Precision in Textile Production