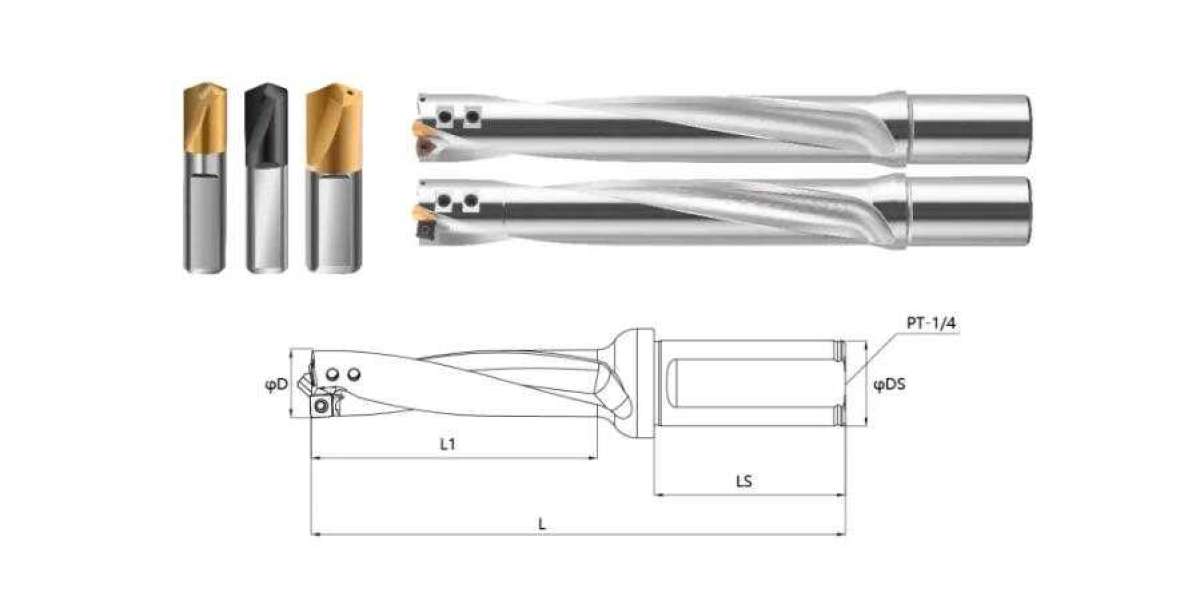

For businesses that rely on drilling tools, balancing cost and performance is a constant challenge. The Replaceable Alloy Drill has become a preferred choice for companies looking to extend tool life while reducing expenses. Unlike conventional drills that require full replacements when worn out, this drill allows users to change only the cutting insert, leading to significant savings on material costs.

One of the notable financial benefits of using a replaceable alloy drill is the reduced need for frequent new purchases. Since the drill body remains intact, businesses can invest in multiple replacement inserts rather than buying entire drill units. Over time, this approach helps lower operational expenses, especially in large-scale machining workshops.

In addition to cost savings, the replaceable alloy drill contributes to sustainability. By minimizing material waste, manufacturers can reduce their environmental impact while maintaining efficient production processes. This aligns with modern industry trends that emphasize resource efficiency and responsible manufacturing.

Furthermore, the easy replacement process ensures that machine downtime is kept to a minimum. Workers can quickly swap out worn drill tips without complex procedures, enhancing productivity and preventing disruptions in workflow. This feature makes the replaceable alloy drill a practical solution for companies focused on long-term economic benefits.

Overall, adopting the replaceable alloy drill is a strategic decision that allows businesses to improve cost efficiency, reduce waste, and maintain consistent performance in machining applications.

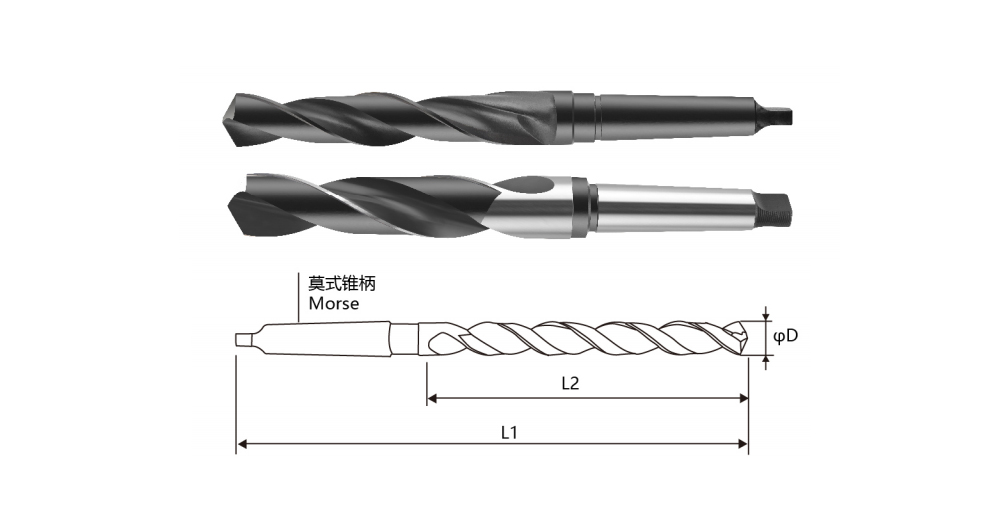

DIN345 4341/6542 tapered shank twist drill is a special drill for metal processing. It is usually made of high-quality 4341 or 6542 high-speed steel materials, which have good hardness and wear resistance, and are suitable for processing a variety of metal materials.