Introduction

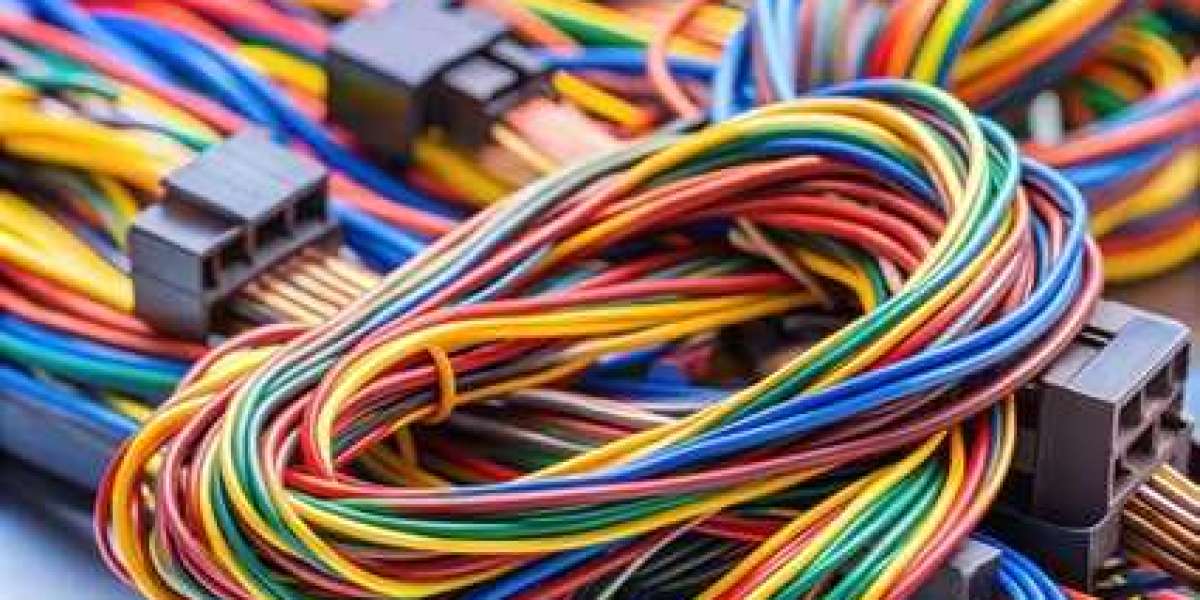

Precision in wire harness connector manufacturing is essential for ensuring reliable electrical associations in various industries, from automotive to aerospace. High accuracy diminishes the gamble of failure, enhances performance, and ensures long-term durability.

Outline

Introduction

Background

Why Precision Matters in Wire Harness Connector Manufacturing

Conclusion

FAQs

Background

Wire harness connectors link parts in electrical systems, making their plan and manufacturing critical for ensuring successful power and data transmission. Precision in manufacturing minimizes screws up and works on the overall functionality of these systems.

Why Precision Matters in Wire Harness Connector Manufacturing

Reliability and Safety

Precision ensures connectors work accurately under various conditions, reducing the gamble of framework failures. This is vital in industries like aerospace and automotive, where safety is non-negotiable.

Performance Optimization

High-precision manufacturing leads to better associations, which advances framework performance by reducing energy disaster and ensuring productive signal transmission.

Longevity and Durability

Accurate manufacturing enhances the lifespan of connectors, preventing wear and tear caused by unfortunate fitting or misalignment, thereby ensuring long-term reliability.

Cost Productivity

Manufacturing connectors with precision minimizes absconds and adjustments, leading to lower production costs and decreased waste, which is essential for maintaining competitiveness in the industry.

Compatibility with Advanced Systems

Current systems require high-speed data transmission and power management. Precision connectors guarantee seamless integration with these advanced technologies, boosting overall viability.

Conclusion

Precision in wire harness connector manufacturing is critical for ensuring reliability, performance, and durability in high-tech industries. It also enhances safety, cost proficiency, and compatibility with present day technologies, making it a key factor in successful product development.

FAQs

1. For what reason is precision important in wire harness connectors?

Precision ensures reliable performance, reducing the risk of system failure and enhancing safety.

2. How does precision affect the performance of connectors?

It enhances associations, reducing energy setbacks and ensuring viable signal transmission.

3. What impact does precision have on the longevity of connectors?

Accurate manufacturing forestalls wear and misalignment, extending the lifespan of connectors.

4. How does precision decrease manufacturing costs?

Precision minimizes abandonment, reducing the necessity for revamp and cutting overall production costs.

5. For what reason is precision important for advanced systems?

Precision ensures that connectors work seamlessly with present day systems, supporting high-speed data transfer and productive power management.