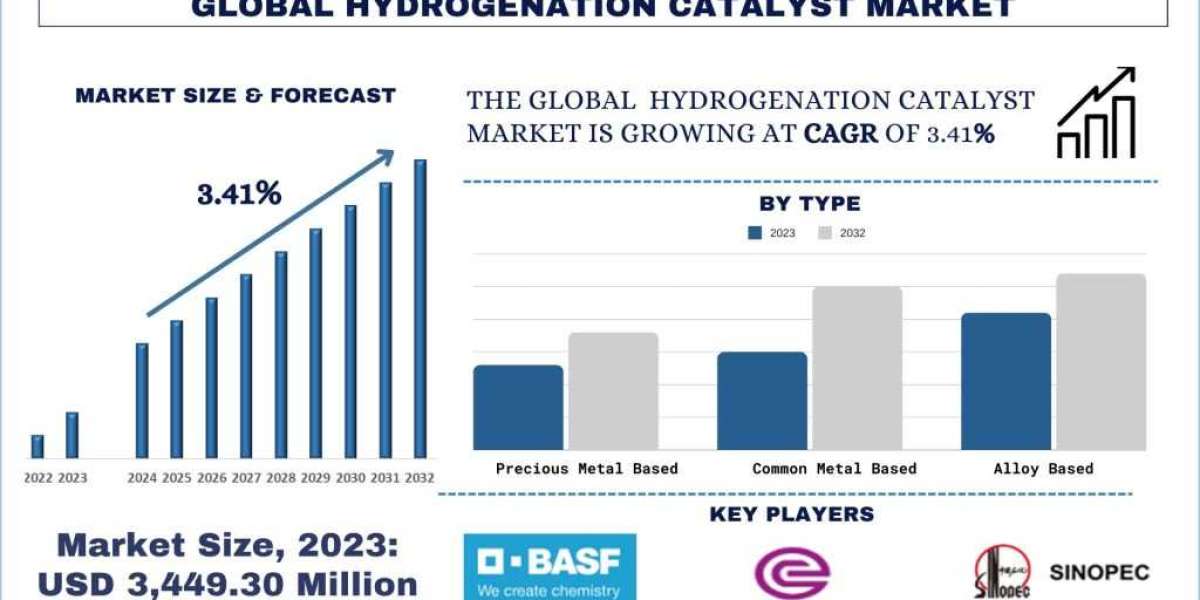

According to a new report by Univdatos Market Insights, the Global Hydrogenation Catalyst Market is expected to reach USD 4,684.95 million in 2032, growing at a CAGR of 3.41%. The market is witnessing substantial growth driven by the increasing demand for cleaner fuels and sustainable chemical processes across various industries, including petrochemicals, pharmaceuticals, and food processing.

Demand:

The following growth drivers in the hydrogenation catalyst market are as follows, first, there is increased demand for clean energy due to changes in social consciousness and government regulations that have tremendously supported this market. The desire of the petroleum processing industry to reduce the sulfur content in fuels, in addition to other environmental concerns, has boosted the call for superior hydrogenation catalysts for use in the industry. Also, due to the high purity requirements of the pharmaceuticals market, this industry has further enhanced the market demand for PTFE products.

Also, the enhanced demand for hydrogenation catalysts for converting edible oils and fats through the hydrogenation process in the food processing sector contributes to the cause. This focus on quality of products, productivity, and concern for the environment has also contributed immensely to its market development.

Applications:

After relentlessly searching for a clean and sustainable energy source, hydrogen has taken a central place in the global quest. The general utilization of hydrogen can be seen in the range of practical applications, mainly when processed using efficient catalysts for fuel cell power and various industrial uses. Hydrogen catalysts have been applied in different industries, such as food, petrochemicals, oil and gas, pharmaceuticals, and others. The process is crucial in the food industry as it enhances food quality and preservation. Hydrogen catalysts, such as nickel-based catalysts, are used to hydrogenate vegetable oils, converting them into semi-solid fats. This process improves the texture and shelf life of food products and enhances their stability. For instance, in October 2022, BASF launched a new line of selective hydrogenation catalysts, the E 15x series, with two innovative products. The new sulfur-resistant E 15x S catalyst family aims to facilitate the processing of contaminated feedstocks, enable reliable process operation, and thereby increase producers' flexibility in using low-quality feedstocks containing higher amounts of impurities. E 153 S ECU 1/8” is now installed in a world-scale PyGas 1st stage unit, proving its outstanding activity and outperforming the competitor's incumbent catalyst. Moreover, in the petrochemical industry, hydrogen catalysts are extensively used in refining processes such as hydrocracking and hydrotreating. These processes involve using catalysts to remove sulfur, nitrogen, and other impurities from crude oil, resulting in cleaner and higher-quality fuels. For instance, Johnson Matthey introduced a new line of palladium-on-carbon (Pd/C) catalysts for pharmaceutical synthesis. These catalysts are designed to enhance the efficiency and selectivity of hydrogenation reactions, resulting in higher yields and purities of APIs.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=62906

Technological Advancements:

The market is experiencing rapid technological developments and significant efforts from top industry players in researching new and efficient hydrogenation catalysts. A notable trend is the use of nanotechnology in catalyst design. On March 10th, 2023, BASF SE introduced a new series of nanostructured hydrogenation catalysts that offer higher activity and selectivity, reducing hydrogenation processes' energy consumption and operational costs.

Furthermore, companies are investing in research and development to discover new catalytic materials and improve existing ones. For instance, in December 2022, Clariant AG announced a collaboration with a leading academic institution to develop next-generation hydrogenation catalysts based on advanced metal-organic frameworks (MOFs) to enhance catalyst efficiency and sustainability.

Conclusion:

The demand for hydrogenation catalysts has risen to the highest levels. It has almost gone unquenchable, benefits to industries that have adopted cleaner productions. The continuous efforts in innovation amongst manufacturers are increasing due to regulatory change, improved technologies, and the requirement for high-performance products. Due to the increasing concern and advances in environmental conservation and effectiveness in chemical processes, the hydrogenation catalyst market is expected to shift and grow over the next few years in an attempt to innovate and come up with the most effective and environmentally sustainable catalysts in the market.

Key Offerings of the Report

Market Size, Trends, Forecast by Revenue | 2024−2032.

Market Dynamics – Leading Trends, Growth Drivers, Restraints, and Investment Opportunities

Market Segmentation – A detailed analysis by Type, by Form, and by End-Use.

Competitive Landscape – Top Key Vendors and Other Prominent Vendors

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com