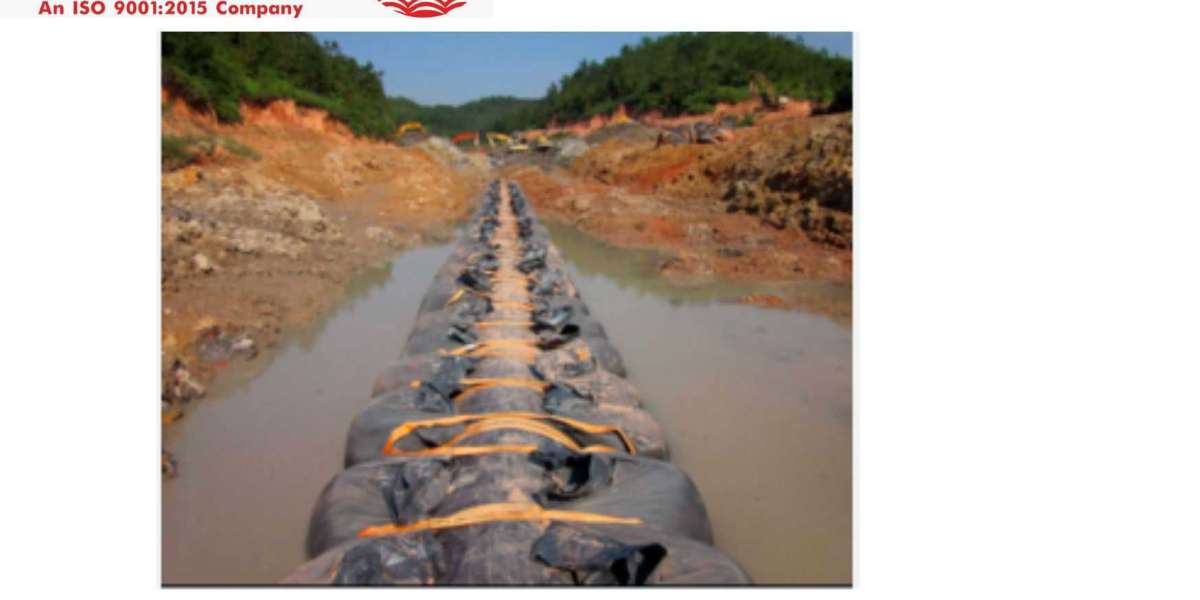

In the construction and infrastructure sectors, ensuring the stability and security of pipeline systems is crucial. One innovative solution to achieve this is through the use of water-filled pipeline weight bags. These specialized bags are designed to provide added weight and stability to pipelines, preventing them from shifting or floating during various construction and environmental conditions. This article will delve into the significance of durable pipeline weight bags, the advantages of custom pipeline weight bags, and their role in maintaining the integrity of pipeline systems.

Understanding Water-Filled Pipeline Weight Bags

Water-filled pipeline weight bags are typically constructed from high-strength materials that can withstand harsh environmental conditions. These bags are filled with water to provide the necessary weight to keep pipelines securely in place. The design allows for easy transportation and placement, making them ideal for various applications, from construction sites to landscaping projects.

One of the primary advantages of using water-filled weight bags is their flexibility. As construction conditions change or as weather patterns shift, the weight bags can be easily adjusted by adding or removing water. This adaptability ensures that pipelines remain stable regardless of external conditions. Moreover, these bags are designed to be durable, providing long-term performance without the risk of deterioration or leakage.

Additionally, water-filled pipeline weight bags are environmentally friendly compared to traditional weights, such as concrete blocks or metal weights. Since they use water as the primary source of weight, they minimize the environmental impact associated with heavy materials. This characteristic makes them a preferred choice for environmentally conscious projects.

The Benefits of Durable Pipeline Weight Bags

Durable pipeline weight bags are engineered to withstand extreme conditions, including temperature fluctuations, UV exposure, and physical stress. The materials used in their construction are typically resistant to tears, punctures, and abrasion, ensuring that the bags maintain their integrity over time. This durability is essential, as pipeline systems are often exposed to challenging environments that can compromise less robust materials.

Moreover, the longevity of durable pipeline weight bags means that construction companies and contractors can rely on them for multiple projects without frequent replacements. This cost-effectiveness is an important factor for businesses operating on tight budgets. Investing in high-quality, durable weight bags can lead to substantial savings over time, as they reduce the need for continual purchases.

The ease of use associated with durable pipeline weight bags also enhances their appeal. They can be quickly deployed and removed as needed, streamlining construction processes and allowing workers to focus on other critical tasks. This efficiency not only saves time but also contributes to safer job sites, as workers can manage weight bags without excessive physical strain.

The Advantage of Custom Pipeline Weight Bags

When it comes to specialized projects, Custom pipeline weight bags provide an invaluable solution. These bags can be tailored to meet the specific requirements of a project, including size, shape, and weight capacity. Customization allows contractors to create solutions that perfectly align with the needs of their pipelines and the unique challenges of their job sites.

One significant benefit of custom pipeline weight bags is the ability to incorporate branding or identification features. Companies can have their logos or project information printed on the bags, which not only enhances visibility on job sites but also promotes brand recognition. This branding can be particularly beneficial for contractors looking to establish their presence in a competitive market.

Furthermore, custom pipeline weight bags can be designed to meet specific regulatory requirements, ensuring that they comply with industry standards. This attention to detail can save time and resources by preventing potential legal issues down the line. Additionally, by collaborating with manufacturers, contractors can explore innovative design features, such as built-in handles or attachment points, making the bags even more functional for their unique needs.

Conclusion

In summary, water-filled pipeline weight bags, durable pipeline weight bags, and custom pipeline weight bags are essential tools in the construction and infrastructure sectors. Their flexibility, durability, and customization options make them indispensable for maintaining the integrity and stability of pipeline systems. As the demand for efficient and reliable construction solutions continues to rise, the use of pipeline weight bags will undoubtedly play a pivotal role in shaping the future of construction practices.

Here are Related For Durable pipeline weight bags

1. How do water-filled pipeline weight bags work?

Water-filled pipeline weight bags work by utilizing water to provide weight and stability to pipelines, preventing them from shifting or floating during construction and environmental changes.

2. What are the advantages of using durable pipeline weight bags?

Durable pipeline weight bags are designed to withstand harsh conditions, offering long-lasting performance and cost-effectiveness, reducing the need for frequent replacements.

3. Can pipeline weight bags be customized?

Yes, custom pipeline weight bags can be tailored to meet specific project needs, including size, shape, and branding, ensuring they align perfectly with the requirements of the job site.