In large-scale infrastructure projects, ensuring the long-term durability and protection of structures from water, chemicals, and environmental elements is essential. One of the most effective solutions for providing this protection is the use of T-Rib HDPE liner sheets. These High-Density Polyethylene (HDPE) liners, featuring a T-Rib structure, offer superior resistance to various environmental challenges, making them a preferred choice in construction, waste management, and water containment applications.

The versatility of T-Rib HDPE liner sheets allows them to be used across a wide range of projects, including landfills, canals, tunnels, and reservoirs. Their unique ribbed design provides additional stability and ensures better adhesion to concrete or other surfaces. In India, as well as in many other regions, these liners have become a standard for projects that require long-lasting, durable solutions for protecting the environment and infrastructure.

What Are T-Rib HDPE Liner Sheets?

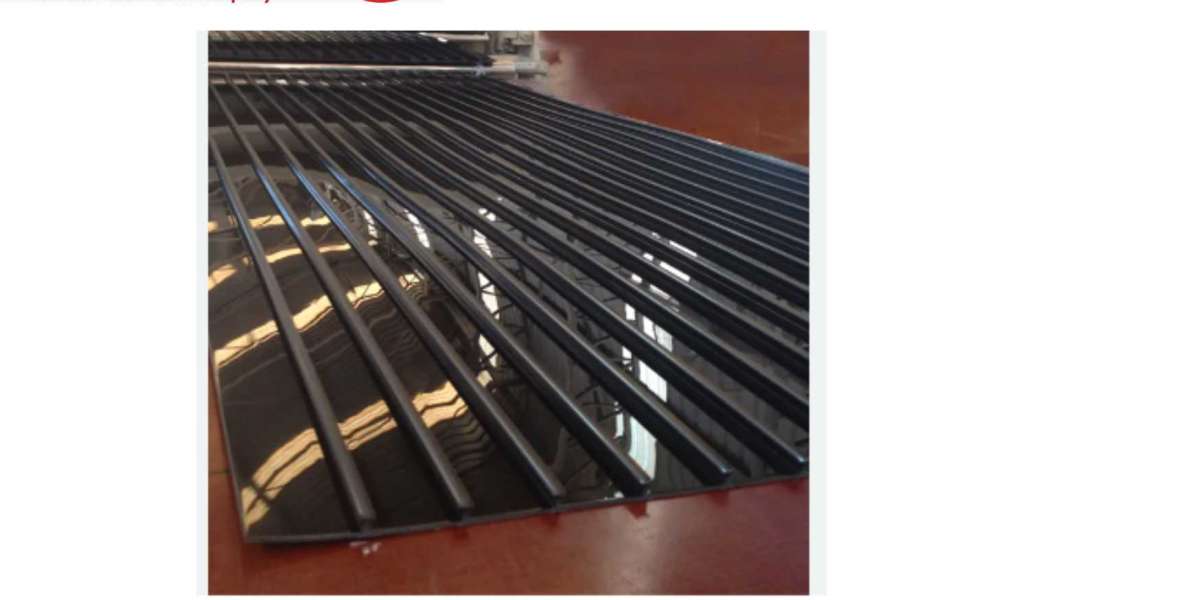

T-Rib HDPE liner sheets are engineered geomembranes made from high-density polyethylene, designed with a ribbed surface to enhance grip and resistance in applications where the liner comes into contact with concrete or other construction materials. These sheets provide a highly impermeable barrier, protecting against water leakage, chemical seepage, and other environmental factors that could otherwise compromise the integrity of the structure.

The ribbed design, unique to T-Rib liners, ensures that the sheet stays firmly in place, reducing the risk of movement or damage over time. This feature is especially valuable in projects involving slopes or vertical surfaces, where traditional smooth liners may struggle to stay secure. In India, T-Rib HDPE liner sheets are widely used in projects such as tunnels, reservoirs, and waste containment sites due to their strength, durability, and cost-effectiveness.

Applications of T-Rib HDPE Liner Sheets

The primary use of T-Rib HDPE liner sheets India and elsewhere is in infrastructure projects that require waterproofing and environmental protection. These liners are used in a variety of industries, from construction to waste management, due to their ability to withstand harsh conditions without compromising on performance.

One of the most common applications is in landfills, where the liner acts as a barrier to prevent leachate—a liquid that can contaminate soil and groundwater—from escaping into the surrounding environment. The T-Rib design ensures that the liner remains securely in place, even when subjected to large volumes of waste and fluctuating ground pressures.

In canal and reservoir construction, T-Rib HDPE liner sheets provide a reliable solution for preventing water loss. The high impermeability of HDPE ensures that water is retained within the structure, reducing the risk of seepage and ensuring efficient water management. In India, where water conservation is critical, the use of T-Rib liners in reservoirs and canals is particularly important.

Additionally, these liners are used in tunnel construction, where they provide a waterproof barrier to protect the structural integrity of the tunnel from water ingress. The ribbed structure ensures that the liner adheres well to the tunnel walls, minimizing the risk of detachment over time.

Benefits of T-Rib HDPE Liner Sheets

The unique design of T-Rib HDPE liner sheets offers several advantages over traditional smooth HDPE liners:

Enhanced Stability: The T-Rib structure provides additional grip, making the liner less likely to shift or move during installation or in response to environmental pressures. This stability is particularly valuable in applications involving slopes or vertical surfaces.

Chemical and UV Resistance: Like other HDPE liners, T-Rib liners are highly resistant to chemicals and ultraviolet (UV) radiation, ensuring long-term durability even when exposed to harsh environmental conditions. This makes them suitable for use in waste containment, chemical storage, and other applications where exposure to harmful substances is common.

Cost-Effective Solution: The long lifespan and minimal maintenance requirements of T-Rib HDPE liners make them a cost-effective solution for infrastructure projects. Once installed, these liners provide lasting protection, reducing the need for costly repairs or replacements.

Easy Installation: Despite their ribbed design, HDPE T-Rib liner sheets installation is relatively straightforward. The sheets are available in large rolls that can be unrolled and positioned on-site, and the ribbed structure helps the liner stay in place during the installation process. Once installed, the liner requires minimal maintenance, providing long-term protection with minimal upkeep.

HDPE T-Rib Liner Sheets Installation Process

Proper HDPE T-Rib liner sheets installation is critical for ensuring the effectiveness of the liner in protecting against water and chemical seepage. The installation process generally follows these steps:

Surface Preparation: Before the liner is installed, the surface must be carefully prepared to ensure a smooth, even foundation. Any debris, rocks, or sharp objects should be removed to prevent punctures or damage to the liner.

Unrolling the Liner: The liner is typically supplied in large rolls, which are unrolled and positioned on the prepared surface. In applications where the liner will be installed on a slope or vertical surface, the ribbed structure helps ensure that the liner stays in place.

Seaming and Welding: Once the liner is in position, the seams between the sheets are welded together to create a continuous, impermeable barrier. This step is crucial for preventing leaks or seepage, as any gaps in the liner could compromise its effectiveness.

Securing the Liner: After the liner is installed and the seams are welded, it is secured in place using appropriate anchors or weights. This ensures that the liner remains stable, even in applications where ground movement or pressure changes are expected.

The entire process requires careful attention to detail, as any mistakes during installation could result in leaks or damage to the liner. It is often recommended that professional installers handle the process to ensure that the liner is properly secured and will provide long-term protection.

The Role of T-Rib HDPE Liner Sheets in Environmental Protection

In addition to their use in infrastructure projects, T-Rib HDPE liner sheets play a critical role in protecting the environment. By preventing the escape of hazardous substances, such as leachate from landfills or chemicals from industrial storage tanks, these liners help safeguard soil and water resources from contamination.

The use of HDPE liners in reservoirs and canals also contributes to water conservation, a particularly important concern in arid regions like parts of India. By preventing water loss through seepage, these liners help ensure that water resources are used efficiently, reducing the need for additional water extraction from natural sources.

Overall, T-Rib HDPE liner sheets are an essential tool for protecting both infrastructure and the environment. Their durability, cost-effectiveness, and ease of installation make them a preferred choice for projects that require long-term protection from water and chemicals.

Conclusion

T-Rib HDPE liner sheets offer a highly effective solution for a wide range of infrastructure and environmental protection projects. With their unique ribbed design, these liners provide enhanced stability and long-lasting protection against water and chemical seepage. Whether used in landfills, reservoirs, canals, or tunnels, T-Rib HDPE liner sheets in India have become an industry standard for projects requiring durable and reliable liners.

When considering the installation of HDPE T-Rib liner sheets, it is essential to work with experienced professionals who understand the nuances of installation to ensure optimal performance. The benefits of these liners, from environmental protection to cost savings, make them an invaluable investment for both public and private projects.

Here are Related For HDPE T-Rib liner sheets installation

Q1: What are the key advantages of using T-Rib HDPE liner sheets?

Ans: T-Rib HDPE liner sheets offer enhanced stability, chemical and UV resistance, and are cost-effective with long-lasting durability. Their ribbed design ensures better adhesion to surfaces, making them ideal for various infrastructure projects.

Q2: How does HDPE T-Rib liner sheets installation differ from traditional liners?

Ans: HDPE T-Rib liners have a ribbed design that enhances grip, making installation on slopes or vertical surfaces more secure. The process involves surface preparation, unrolling, seaming, and securing the liner for optimal protection.

Q3: Where are T-Rib HDPE liner sheets commonly used?

Ans: These liners are used in landfills, canals, reservoirs, tunnels, and other infrastructure projects requiring water and chemical containment to protect both the environment and structures.