The aramid fiber market has witnessed significant growth in recent years, driven by the increasing demand for lightweight, durable, and heat-resistant materials across various industries. Aramid fibers, which include well-known brands such as Kevlar and Nomex, are synthetic fibers characterized by their high strength, low density, and excellent resistance to heat, chemicals, and abrasion. This makes them an ideal choice for applications in sectors like aerospace, defense, automotive, and protective clothing.

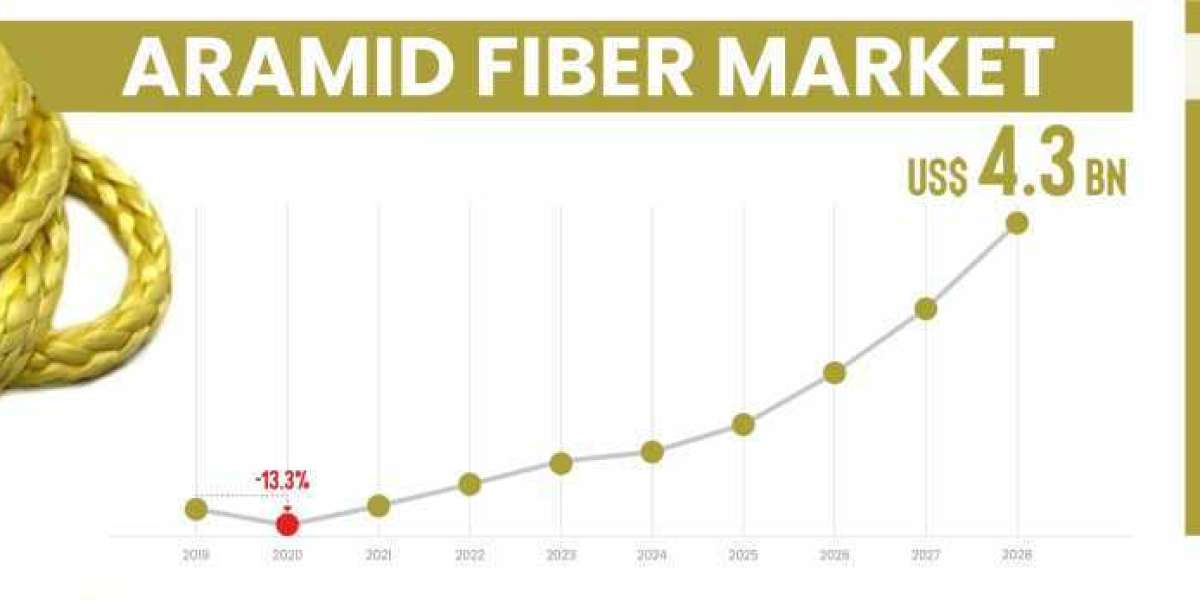

The aramid fiber market is likely to grow at a moderate CAGR of 4.3% in the long run to reach US$ 4.3 Billion in 2028.

Market Overview and Key Drivers

The global aramid fiber market is expected to continue its upward trend, with several factors contributing to its growth. One of the primary drivers is the increasing demand for lightweight and high-strength materials in the automotive and aerospace industries. These industries are constantly seeking materials that reduce weight to improve fuel efficiency and reduce emissions, while still offering superior mechanical performance. Aramid fibers fulfill these requirements due to their exceptional strength-to-weight ratio.

In the defense and military sector, the demand for aramid fibers has risen due to their use in bulletproof vests, helmets, and other protective gear. These fibers offer enhanced protection without compromising on flexibility or comfort, making them crucial for modern military applications. Similarly, the use of aramid fibers in firefighting and other emergency response equipment is growing due to their flame-resistant properties.

Another major driver is the increasing emphasis on sustainability and environmental regulations. As industries strive to reduce their environmental impact, aramid fibers—being durable and long-lasting—are being considered for applications where material longevity and reduced waste are critical.

Challenges in the Market

Despite its promising growth, the aramid fiber market faces several challenges. One of the major hurdles is the high cost of production, which limits its widespread adoption, particularly in cost-sensitive industries. The manufacturing process of aramid fibers involves complex chemical reactions, which contribute to the overall cost. Additionally, the market faces competition from other high-performance fibers like carbon fiber and ultra-high-molecular-weight polyethylene (UHMWPE), which are also gaining popularity in various applications.

Future Prospects

Looking ahead, the aramid fiber market is expected to see further growth, driven by technological advancements and expanding applications. Innovations in manufacturing processes could help reduce costs, making aramid fibers more accessible to a broader range of industries. Additionally, the ongoing focus on research and development is likely to introduce new aramid-based composites, further enhancing their performance and broadening their applications.

In conclusion, while the aramid fiber market presents substantial growth potential, addressing the challenges of high production costs and competition will be crucial for long-term success. With the growing demand for high-performance, lightweight, and durable materials, the future of the aramid fiber market remains promising.

To know in detail about the market dynamics, Register here: https://www.stratviewresearch.com/Request-Sample/165/aramid-fiber-market.html#form