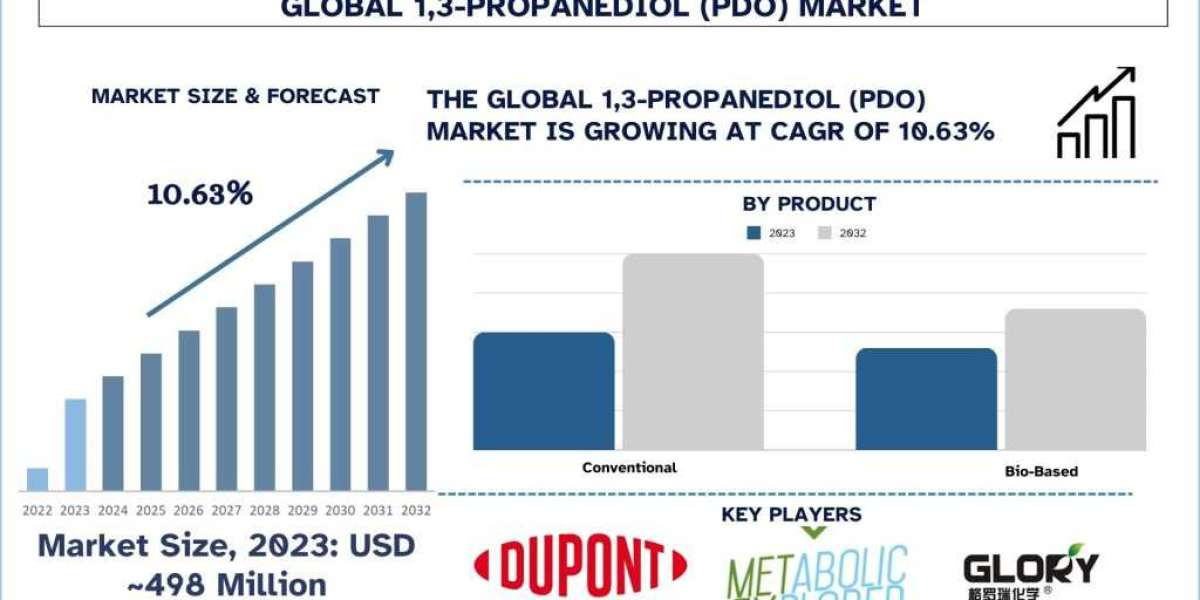

According to the UnivDatos Market Insights, “1,3-Propanediol (PDO) Market” report, the global market was valued at USD 498 Million in 2023 and growing at a CAGR of 10.63% during the forecast period from 2024 – 2032.

The 1,3-propanediol (PDO) market is growing rapidly because of its uses across a variety of sectors including textiles, personal care, and plastics among others. The analysis of demand and supply factors and the value chain and price analysis offer insight into the Global PDO market. In particular, this article focuses on elements such as the demands side, supply chain aspects, and the pricing factors of the market.

Global Demand for PDO

Industrial Applications: The primary use of PDO is in the production of PTT, which is a bio-based polymer experiencing high demand due to its high performance in textiles and carpets. Some of the properties of PTT that have led to its extensive use include high rubber-like properties, stain resistance, and durability, especially in the fashion and home furnishing industries.

Technological Advancements: With the improved technologies in PDO production, especially fermentation from bio sources, PDO has become more reachable and inexpensive. These technologies have stirred the pragmatic and cost-saving aspects that have greatly expanded the uses as well as the market frontiers of PDO.

Sustainability Trends: Increased focus on sustainability around the world continues to be a major signal of PDO demand. Consumers and industries are in continuous search of bio-based and renewably sourced products in their bid to lessen their negative impact on the environment. PDO being one of the major players in the production of biodegradable materials and being in harmony with the most current trend of using sustainable textiles, tends to be more popular and is used in many applications. Efforts towards green manufacturing and packaging on its products based on PDO also add to the market expansion supporting its growth.

Global Supply of PDO

Production Capacity: The major PDO suppliers are found in strategic locations such as North America, Europe, and Asia-Pacific. North America especially the United States of America is the leading producer of PDO due to its technology and large-scale industries. Some of the key acting supply players include PDOs such as DuPont and Global Bioenergies in this region. Another essential production site is Europe where through their excellent production machinery developed by BASF and DSM companies push through the supplies.

Raw Material Availability: PDO production takes advantage of such renewable raw materials as cornstarch and sugarcane. The main raw materials that affect PDO therefore availability is its supply in the market and its cost. Developed countries – for instance, the United States and Brazil, that are the major producers of agricultural raw materials obtain stable supply and, hence can produce PDO continuously.

Supply Chain Dynamics: The PDO supply chain covers many aspects such as sourcing of raw materials, manufacturing, and distribution. Manufacturers face the challenges of procuring renewable materials, maintaining production plants, and supplying to consumers across the world. Geopolitical instabilities or natural disasters may affect PDO distribution and as an extension its prices.

Value Chain Analysis

Raw Material Suppliers: The value chain of PDO starts with the upstream suppliers which are involved in supplying the raw materials in the production process. These suppliers help to ensure the solid supply of the high-quality corn or sugarcane that is vital for bio-based PDO production. The way they perform and the reliability they offer are some of the things that determine the value chain.

Manufacturers: PDO manufacturers are directly involved in the value chain since they are involved with the manufacturing of PDO through a series of processes from raw materials. For instance, the large-scale manufacturers of PDOs who have invested in the latest production technologies like fermentation-based production improve the productivity and capacity of PDO production. Competing costs and product quality of PDO are two primary parameters relevant to the subject value chain that shape market competencies.

Distributors and Retailers: After being manufactured, PDO can be purchased by different end-users from industries via distributors and stores. Marketing channels are also critical in guaranteeing timely delivery of products and at the same time, guaranteeing product quality. They are part of the supply chain which has the major responsibility of ensuring that manufacturers reach their target market and cater to the demand.

End-Use Industries: The last component of the value chain of PDO involves the application of the substance in different products including textile products, body products, and plastics. Consumers include end-use industries that set PDO market value depending on the efficiency of the product as well as the need it fulfills. These determine the varieties and volumes of PDO produced and therefore control the value chain.

Pricing Analysis

Production Costs: PDO’s pricing strategy is also affected by production cost factors, raw material costs, and technological aspects. The transition to bio-based production approaches has initially caused increased costs of production in comparison with petroleum-based chemicals. However, with time and advancement in technology as well as experience, the costs have been coming down which explains price competitiveness.

Access sample report (including graphs, charts, and figures): https://univdatos.com/get-a-free-sample-form-php/?product_id=66259

Market Demand: Fluctuations of demand across completely different regions and applications influence PDO pricing. High demand for PDOs for textiles and personal care products results in higher prices, especially where there is a shortage in the supply. On the other hand, a decrease in demand or production excess can apply pressure that lowers the price level. Changes experienced in the market and consumer preferences are some of the factors that dictate the price changes of PDO.

Geopolitical and Economic Factors: Market changes, consumer behavior and market policies such as geopolitical events, economic circumstances, and trade relations also affect the PDO price. For instance, the cost of raw materials like trade tariffs, import/export regulations, and fluctuations in currencies can impact the cost of PDO and therefore its price. Both the producers and the consumers have to consider these scenarios in determining pricing and overall stability in the market.

Competitive Landscape: Pricing policies of PDOs depend on the competition that is present within the PDO market. Some industries are very competitive and as a result, there may be cases whereby companies involved engage in pricing strategies such as selling at a cheaper price to capture a certain market share. Competition is a key factor in this market highlighted by the presence of many players this affects the PDO prices and the market on the whole.

Conclusion

The global PDO market is influenced by forces such as demand and supply forces, value-adding components of the PDO, and issues of pricing. Technological developments and sustainability trends have skewed the demand for PDO towards apparel and textiles, personal care products, and bio-based plastics. On the supply side, the major production centers of North America, Europe, and the Asia-Pacific region are prominent, as production capability and availability of the raw material define the market. The value chain, in this case, consists of raw material suppliers, manufacturers, distributors, and end-use industries which are all important segments of the market. Pricing strategy focuses on how production costs, demand, geopolitics, and competitor pressure affect PDO price.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com