HDPE liner sheets are widely recognized for their versatility and durability in various environmental and industrial applications. In India, these liners have gained significant traction due to their excellent resistance to chemicals, UV radiation, and physical stress. HDPE, or high-density polyethylene, is a material that provides exceptional impermeability, making it an ideal choice for lining containment areas like landfills, reservoirs, and wastewater treatment facilities. HDPE liner sheets India suppliers cater to diverse needs, offering sheets in different thicknesses and sizes suitable for various project requirements.

One of the primary benefits of using HDPE liner sheets india is their ability to prevent contamination of groundwater by providing an effective barrier against toxic substances. Their robust nature ensures that they can withstand harsh conditions without deteriorating, which is crucial for long-term projects. Industries such as agriculture, mining, and construction often rely on HDPE liners for water retention systems, leachate control, and other containment solutions. As the demand for sustainable infrastructure grows, the use of HDPE liner sheets in India continues to expand, supporting efforts to protect the environment while meeting industrial needs.

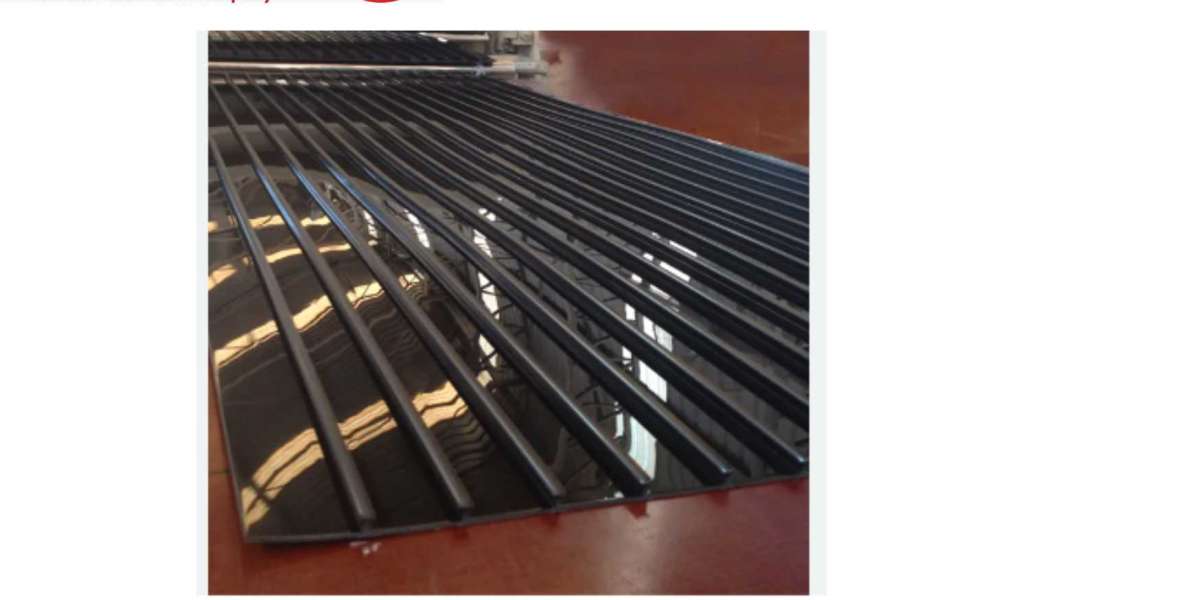

T Rib HDPE Liner Sheets: Enhanced Strength for Demanding Applications

T Rib HDPE liner sheets offer an advanced solution for situations where additional strength and support are required. These specially designed sheets feature rib-like structures on one side, providing extra grip and preventing slippage when installed in vertical or steeply inclined surfaces. This makes T Rib HDPE liner sheets particularly useful in applications such as lining tunnels, canals, and embankments, where stability is essential. The ribbed design helps the liner adhere more securely to the substrate, reducing the risk of movement and enhancing the overall performance of the liner system.

The increased surface friction provided by T Rib HDPE liner sheets also helps to prevent the accumulation of water between the liner and the substrate, reducing the likelihood of water pressure buildup that could compromise the liner's integrity. This characteristic is beneficial for drainage applications and other water management systems where reliable containment is necessary. The ribbed liners are made from the same durable high-density polyethylene as standard HDPE liners, ensuring long-lasting performance in even the most demanding environments.

HDPE Rib Liner Sheets Installation: Ensuring Optimal Performance

Proper HDPE rib liner sheets installation is crucial for achieving the intended performance and durability of the liner system. The installation process involves careful preparation of the site, including the removal of sharp objects and debris that could damage the liner. The T Rib HDPE liner sheets should be unrolled and positioned with the ribbed side facing the substrate to maximize friction and stability. Depending on the project requirements, the sheets can be welded together using heat-sealing techniques, creating a seamless and impermeable barrier that effectively prevents leaks.

For applications such as tunnel lining or steep embankments, additional steps may be needed to anchor the liner securely in place. This could involve using mechanical fasteners or other specialized techniques to prevent the liner from slipping or shifting over time. Ensuring a tight seal around the edges and seams is also critical to avoid water ingress and to maintain the structural integrity of the liner system. Working with experienced installation professionals is recommended for complex projects to ensure that the HDPE Rib liner sheets installation correctly and function as intended throughout their lifespan.

Exploring the Benefits of HDPE Pond Liners for Your Water Features

If you’re looking to create or maintain a stunning pond, investing in high-quality HDPE pond liners is essential. As a robust solution for pond construction, HDPE (High-Density Polyethylene) pond liners offer exceptional durability and reliability. When searching for HDPE pond liner for sale, it’s important to consider factors such as thickness, UV resistance, and the specific needs of your water feature.

One of the leading advantages of HDPE pond liners is their resistance to punctures and tears, which makes them ideal for both small decorative ponds and larger water bodies. They can withstand extreme weather conditions and have a long lifespan, ensuring your pond remains intact for years to come. This durability is a crucial consideration when selecting a pond liner manufacturer; reliable manufacturers provide products that meet industry standards and offer warranties to back their claims.

When you choose an HDPE pond liner, you’re also making an eco-friendly choice. These liners are recyclable and do not leach harmful chemicals into the water, making them safe for fish and aquatic plants. Additionally, their flexibility allows for easy installation, accommodating various pond shapes and sizes.

Before making a purchase, it’s beneficial to compare different options and consult with professionals in the field. They can guide you toward the best products suited to your specific requirements.

In summary, HDPE pond liners are a top choice for pond owners due to their durability, environmental safety, and ease of installation. By sourcing your HDPE pond liner for sale from reputable manufacturers, you can ensure a long-lasting and beautiful addition to your landscape.

Conclusion

HDPE liner sheets are a reliable and versatile solution for a wide range of containment and environmental protection applications in India. Their durability, chemical resistance, and impermeability make them ideal for industrial uses such as landfill liners, reservoir liners, and wastewater treatment facilities. T Rib HDPE liner sheets provide an enhanced option for projects requiring additional strength and stability, especially on vertical or inclined surfaces. Proper HDPE rib liner sheets installation is essential for ensuring optimal performance, with careful site preparation and skilled installation techniques contributing to the effectiveness and longevity of the liner system. As awareness of sustainable practices continues to grow, the use of HDPE liner sheets in India is likely to increase, supporting the development of eco-friendly and safe infrastructure.

Frequently Asked Questions

Q1: What factors should be considered when choosing HDPE liner sheets in India?

Ans: Consider the thickness, size, and specific application requirements, as well as the environmental conditions and potential exposure to chemicals or UV radiation.

Q2: Why are T Rib HDPE liner sheets preferred for steep or vertical surfaces?

Ans: The ribbed design increases surface friction, preventing slippage and providing additional stability in challenging installations like steep embankments or tunnels.

Q3: How can I ensure a successful HDPE rib liner sheets installation?

Ans: Proper site preparation, skilled installation, and sealing of edges and seams are crucial for maintaining the liner's integrity and preventing leaks.